Page 360 - Refining Biomass Residues for Sustainable Energy and Bioproducts

P. 360

(2017)

(2019)

(2019)

(2017)

(2018)

(2019)

(2019)

Amin

Amin

al.

al.

al.

al.

al.

al.

al.

and

and

(2016)

(2016)

et

et

et

et

et

et

et

Ramli

Ramli

Tiong

Tiong

Tiong

Tiong

Guan

Jahar

Jahar

Ref.

yield

43.75

16.37

21.1 a

14.7 a

18.7 a

13.1 a

20.1 a

16.2

12.8

(%)

AL

Time

condition

10.0

10.0

12.2

12.2

10.0

2.0

1.0

2.0

5.0

(h)

Reaction

Temp.

105.0

105.0

200.0

78.4

( C)

78.4

90.0

90.0

180

180

Solvent

MeOH

MeOH

EtOH

EtOH

EtOH

EtOH

EtOH

EtOH

EtOH

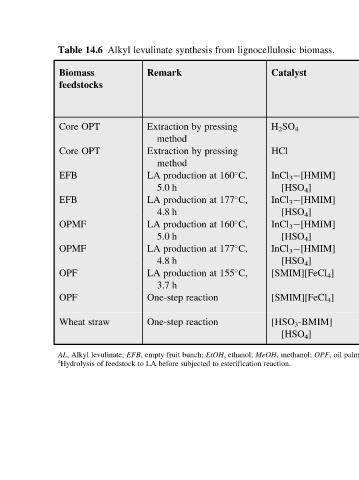

palm trunk. palm oil OPT, fiber; mesocarp palm OPMF, oil frond;

oil

biomass. InCl 3 [HMIM] [HSO 4 ] InCl 3 [HMIM] [HSO 4 ] InCl 3 [HMIM] [HSO 4 ] InCl 3 [HMIM] [HSO 4 ] [SMIM][FeCl 4 ] [SMIM][FeCl 4 ] [HSO 3 -BMIM] [HSO 4 ] OPF,

lignocellulosic Catalyst H 2 SO 4 HCl MeOH, methanol; reaction.

from pressing pressing 160 C, at 177 C, at 160 C, at 177 C, at 155 C, at EtOH, ethanol; to esterification

synthesis by by production h production h production h production h production h reaction reaction bunch; subjected

levulinate Remark Extraction method Extraction method LA 5.0 LA 4.8 LA 5.0 LA 4.8 LA 3.7 One-step One-step fruit EFB, empty before LA to

Alkyl levulinate; feedstock

14.6 OPT OPT straw of

Table Biomass feedstocks Core Core EFB EFB OPMF OPMF OPF OPF Wheat Alkyl AL, a Hydrolysis