Page 335 - Renewable Energy Devices and System with Simulations in MATLAB and ANSYS

P. 335

322 Renewable Energy Devices and Systems with Simulations in MATLAB and ANSYS ®

®

TABLE 13.1

Worldwide Installed Electrical Energy Storage Capacity Based on

Fraunhofer Institute Data and Rastler, EPRI, Technical Update, 2010

Energy Storage Technology Installed Capacity (MW)

Pumped hydro 127,000

Compressed air energy storage (CAES) 440

Sodium sulfur battery (NaS) 316

Lead-acid battery 35

Nickel-cadmium battery 27

Flywheels 25

Lithium-ion battery 20

Redox flow battery 3

NaS

Li-ion

10 2 Redox

NiMH

Energy density (Wh/kg) 10 1 Lead- flow Flywheel Ultracapacitor

acid

10 0

10 2 10 3 10 4

Power density (W/kg)

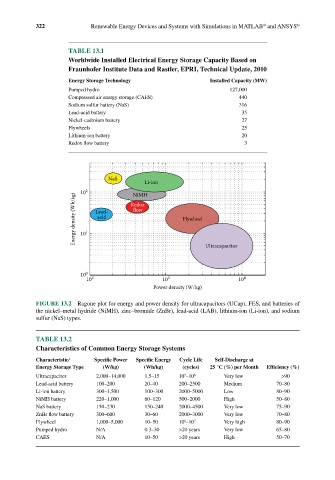

FIGURE 13.2 Ragone plot for energy and power density for ultracapacitors (UCap), FES, and batteries of

the nickel–metal hydride (NiMH), zinc–bromide (ZnBr), lead-acid (LAB), lithium-ion (Li-ion), and sodium

sulfur (NaS) types.

TABLE 13.2

Characteristics of Common Energy Storage Systems

Characteristic/ Specific Power Specific Energy Cycle Life Self-Discharge at

Energy Storage Type (W/kg) (Wh/kg) (cycles) 25 °C (%) per Month Efficiency (%)

Ultracapacitor 2,000–14,000 1.5–15 10 –10 6 Very low >90

5

Lead-acid battery 100–200 20–40 200–2500 Medium 70–80

Li-ion battery 300–1,500 100–300 2000–5000 Low 80–90

NiMH battery 220–1,000 60–120 500–2000 High 50–80

NaS battery 150–230 150–240 2000–4500 Very low 75–90

ZnBr flow battery 300–600 30–60 2000–3000 Very low 70–80

Flywheel 1,000–5,000 10–50 10 –10 7 Very high 80–90

5

Pumped hydro N/A 0.3–30 >20 years Very low 65–80

CAES N/A 10–50 >20 years High 50–70