Page 181 - Robot Builder's Bonanza

P. 181

150 RAPID PROTOTYPING METHODS

foam, usually either 1/32″ or 1/8″ thick, and from 1/4″ to over 1″ wide. The tape is coated

with an aggressive adhesive on both sides. To use, peel off the protective paper and apply the

tape between the parts to be joined. The adhesive is pressure- sensitive and cures to a strong

bond within 24 hours.

Many consumer- grade foam tapes are engineered with an adhesive that never fully cures.

It stays gummy so that the tape can be more readily removed from walls. Maybe this is what

you want, or maybe not. For a more permanent bond, look for industrial- grade double- sided

foam tape; it’s available at better hardware stores, as well as industrial supply mail- order out-

lets, such as McMaster- Carr. One such product is 3M VHB self- adhesive tape.

CABLE CLAMPS

Motors need to be fastened to the base of the robot in such a way that they won’t easily come

off or go crooked. Motor shafts akimbo result in misaligned wheels, which make your bot

harder to control and steer.

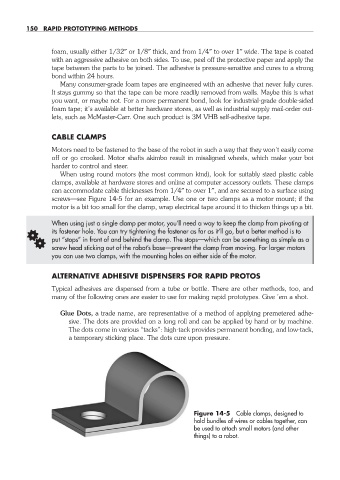

When using round motors (the most common kind), look for suitably sized plastic cable

clamps, available at hardware stores and online at computer accessory outlets. These clamps

can accommodate cable thicknesses from 1/4″ to over 1″, and are secured to a surface using

screws— see Figure 14-5 for an example. Use one or two clamps as a motor mount; if the

motor is a bit too small for the clamp, wrap electrical tape around it to thicken things up a bit.

When using just a single clamp per motor, you’ll need a way to keep the clamp from pivoting at

G its fastener hole. You can try tightening the fastener as far as it’ll go, but a better method is to

put “stops” in front of and behind the clamp. The stops— which can be something as simple as a

screw head sticking out of the robot’s base— prevent the clamp from moving. For larger motors

you can use two clamps, with the mounting holes on either side of the motor.

ALTERNATIVE ADHESIVE DISPENSERS FOR RAPID PROTOS

Typical adhesives are dispensed from a tube or bottle. There are other methods, too, and

many of the following ones are easier to use for making rapid prototypes. Give ’em a shot.

Glue Dots, a trade name, are representative of a method of applying premetered adhe-

sive. The dots are provided on a long roll and can be applied by hand or by machine.

The dots come in various “tacks”: high- tack provides permanent bonding, and low- tack,

a temporary sticking place. The dots cure upon pressure.

Figure 14-5 Cable clamps, designed to

hold bundles of wires or cables together, can

be used to attach small motors (and other

things) to a robot.

14-chapter-14.indd 150 4/21/11 11:48 AM