Page 206 - Robot Builder's Bonanza

P. 206

USING WOOD AND PLASTIC SAMPLES 175

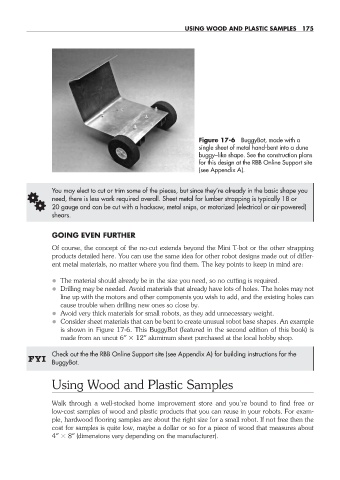

Figure 17-6 BuggyBot, made with a

single sheet of metal hand- bent into a dune

buggy–like shape. See the construction plans

for this design at the RBB Online Support site

(see Appendix A).

You may elect to cut or trim some of the pieces, but since they’re already in the basic shape you

G need, there is less work required overall. Sheet metal for lumber strapping is typically 18 or

20 gauge and can be cut with a hacksaw, metal snips, or motorized (electrical or air- powered)

shears.

GOING EVEN FURTHER

Of course, the concept of the no- cut extends beyond the Mini T- bot or the other strapping

products detailed here. You can use the same idea for other robot designs made out of differ-

ent metal materials, no matter where you find them. The key points to keep in mind are:

• The material should already be in the size you need, so no cutting is required.

• Drilling may be needed. Avoid materials that already have lots of holes. The holes may not

line up with the motors and other components you wish to add, and the existing holes can

cause trouble when drilling new ones so close by.

• Avoid very thick materials for small robots, as they add unnecessary weight.

• Consider sheet materials that can be bent to create unusual robot base shapes. An example

is shown in Figure 17-6. This BuggyBot (featured in the second edition of this book) is

made from an uncut 6″ 12″ aluminum sheet purchased at the local hobby shop.

Check out the the RBB Online Support site (see Appendix A) for building instructions for the

FYI BuggyBot.

Using Wood and Plastic Samples

Walk through a well- stocked home improvement store and you’re bound to find free or

low- cost samples of wood and plastic products that you can reuse in your robots. For exam-

ple, hardwood flooring samples are about the right size for a small robot. If not free then the

cost for samples is quite low, maybe a dollar or so for a piece of wood that measures about

4″ 8″ (dimensions vary depending on the manufacturer).

17-chapter-17.indd 175 4/21/11 11:49 AM