Page 282 - Robot Builder's Bonanza

P. 282

CONTROL SIGNALS FOR R/C SERVOS 251

The motor and potentiometer are connected to a control board, all three of which form a

closed feedback loop. The servo is powered by 4.8 to 7.2 volts.

G You can’t run an R/C servo simply by connecting it to a battery. It needs special control signals

to operate. As it turns out, it’s not terribly hard to control a servo using simple programming.

Numerous programming examples are provided in Part 7.

LIMITING ROTATION

As you can surmise, servo motors are designed for limited rotation rather than for continuous

rotation like a DC motor. While there are servos that rotate continuously, and you can modify

one to freely rotate (see later in this chapter), the primary use of the R/C servo is to achieve

accurate rotational positioning over a range of up to 180°.

While 180°—half a circle— may not sound like much, in actuality such control can be used

to steer a robot, move legs up and down, rotate a sensor to scan the room, and more. The

precise angular rotation of a servo in response to a specific digital signal has enormous uses

in all fields of robotics.

Control Signals for R/C Servos

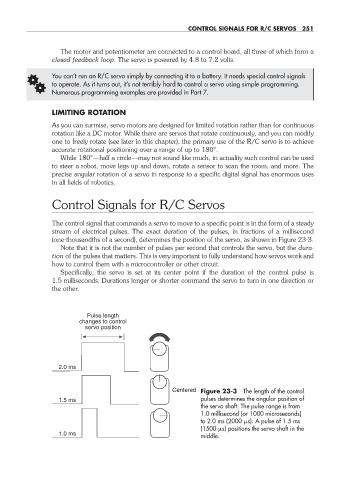

The control signal that commands a servo to move to a specific point is in the form of a steady

stream of electrical pulses. The exact duration of the pulses, in fractions of a millisecond

(one- thousandths of a second), determines the position of the servo, as shown in Figure 23- 3.

Note that it is not the number of pulses per second that controls the servo, but the dura-

tion of the pulses that matters. This is very important to fully understand how servos work and

how to control them with a microcontroller or other circuit.

Specifically, the servo is set at its center point if the duration of the control pulse is

1.5 milliseconds. Durations longer or shorter command the servo to turn in one direction or

the other.

Pulse length

changes to control

servo position

2.0 ms

Centered Figure 23- 3 The length of the control

1.5 ms pulses determines the angular position of

the servo shaft. The pulse range is from

1.0 millisecond (or 1000 microseconds)

to 2.0 ms (2000 s). A pulse of 1.5 ms

(1500 s) positions the servo shaft in the

1.0 ms

middle.

23-chapter-23.indd 251 4/21/11 11:51 AM