Page 347 - Robot Builder's Bonanza

P. 347

316 BUILD ROBOTS WITH WHEELS AND TRACKS

Cut out the wood or plastic for the top deck, and secure it in place over

the hex standoffs using 4- 40 1/2″ screws.

BEST STEERING FOR TRACKED ROBOTS

Because a tank track exposes a considerable amount of its surface onto

the ground at any one time, in a turn the tracks must actually slip, or

skid, over the earth. The part of the track farthest from the midpoint of

the vehicle skids the most.

Unlike a differentially steered two- wheel bot, where it is possible to

turn by simply stopping one wheel, this is not advisable with a track

drive. The track exposes too much surface area to the ground, which

greatly increases friction. The stopped track will skitter over the ground

(and possibly come off), and turning is harder to control.

SPECIAL CONSIDERATIONS FOR RUBBER TREADS

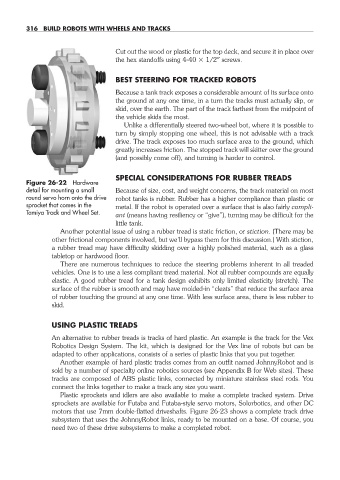

Figure 26- 22 Hardware

detail for mounting a small Because of size, cost, and weight concerns, the track material on most

round servo horn onto the drive robot tanks is rubber. Rubber has a higher compliance than plastic or

sprocket that comes in the metal. If the robot is operated over a surface that is also fairly compli-

Tamiya Track and Wheel Set. ant (means having resiliency or “give”), turning may be difficult for the

little tank.

Another potential issue of using a rubber tread is static friction, or stiction. (There may be

other frictional components involved, but we’ll bypass them for this discussion.) With stiction,

a rubber tread may have difficulty skidding over a highly polished material, such as a glass

tabletop or hardwood floor.

There are numerous techniques to reduce the steering problems inherent in all treaded

vehicles. One is to use a less compliant tread material. Not all rubber compounds are equally

elastic. A good rubber tread for a tank design exhibits only limited elasticity (stretch). The

surface of the rubber is smooth and may have molded- in “cleats” that reduce the surface area

of rubber touching the ground at any one time. With less surface area, there is less rubber to

skid.

USING PLASTIC TREADS

An alternative to rubber treads is tracks of hard plastic. An example is the track for the Vex

Robotics Design System. The kit, which is designed for the Vex line of robots but can be

adapted to other applications, consists of a series of plastic links that you put together.

Another example of hard plastic tracks comes from an outfit named JohnnyRobot and is

sold by a number of specialty online robotics sources (see Appendix B for Web sites). These

tracks are composed of ABS plastic links, connected by miniature stainless steel rods. You

connect the links together to make a track any size you want.

Plastic sprockets and idlers are also available to make a complete tracked system. Drive

sprockets are available for Futaba and Futaba- style servo motors, Solorbotics, and other DC

motors that use 7mm double- flatted driveshafts. Figure 26- 23 shows a complete track drive

subsystem that uses the JohnnyRobot links, ready to be mounted on a base. Of course, you

need two of these drive subsystems to make a completed robot.

26-chapter-26.indd 316 4/21/11 11:52 AM