Page 348 - Robot Builder's Bonanza

P. 348

BUILDING TANK- STYLE ROBOTS 317

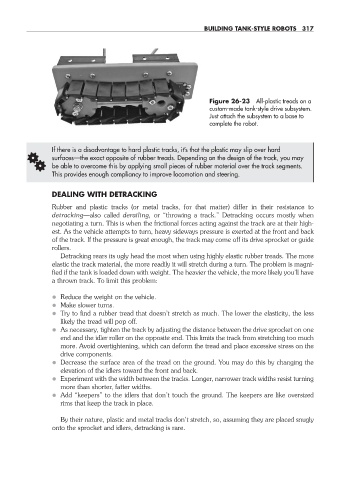

Figure 26- 23 All- plastic treads on a

custom- made tank- style drive subsystem.

Just attach the subsystem to a base to

complete the robot.

If there is a disadvantage to hard plastic tracks, it’s that the plastic may slip over hard

G surfaces— the exact opposite of rubber treads. Depending on the design of the track, you may

be able to overcome this by applying small pieces of rubber material over the track segments.

This provides enough compliancy to improve locomotion and steering.

DEALING WITH DETRACKING

Rubber and plastic tracks (or metal tracks, for that matter) differ in their resistance to

detracking— also called derailing, or “throwing a track.” Detracking occurs mostly when

negotiating a turn. This is when the frictional forces acting against the track are at their high-

est. As the vehicle attempts to turn, heavy sideways pressure is exerted at the front and back

of the track. If the pressure is great enough, the track may come off its drive sprocket or guide

rollers.

Detracking rears its ugly head the most when using highly elastic rubber treads. The more

elastic the track material, the more readily it will stretch during a turn. The problem is magni-

fied if the tank is loaded down with weight. The heavier the vehicle, the more likely you’ll have

a thrown track. To limit this problem:

• Reduce the weight on the vehicle.

• Make slower turns.

• Try to find a rubber tread that doesn’t stretch as much. The lower the elasticity, the less

likely the tread will pop off.

• As necessary, tighten the track by adjusting the distance between the drive sprocket on one

end and the idler roller on the opposite end. This limits the track from stretching too much

more. Avoid overtightening, which can deform the tread and place excessive stress on the

drive components.

• Decrease the surface area of the tread on the ground. You may do this by changing the

elevation of the idlers toward the front and back.

• Experiment with the width between the tracks. Longer, narrower track widths resist turning

more than shorter, fatter widths.

• Add “keepers” to the idlers that don’t touch the ground. The keepers are like oversized

rims that keep the track in place.

By their nature, plastic and metal tracks don’t stretch, so, assuming they are placed snugly

onto the sprocket and idlers, detracking is rare.

26-chapter-26.indd 317 4/21/11 11:52 AM