Page 83 - Robot Builder's Bonanza

P. 83

52 BUILDING ROBOT BODIES— THE BASICS

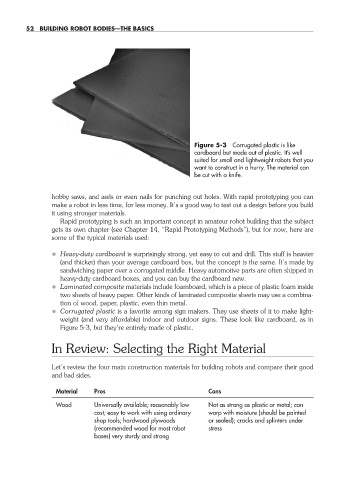

Figure 5-3 Corrugated plastic is like

cardboard but made out of plastic. It’s well

suited for small and lightweight robots that you

want to construct in a hurry. The material can

be cut with a knife.

hobby saws, and awls or even nails for punching out holes. With rapid prototyping you can

make a robot in less time, for less money. It’s a good way to test out a design before you build

it using stronger materials.

Rapid prototyping is such an important concept in amateur robot building that the subject

gets its own chapter (see Chapter 14, “Rapid Prototyping Methods”), but for now, here are

some of the typical materials used:

• Heavy- duty cardboard is surprisingly strong, yet easy to cut and drill. This stuff is heavier

(and thicker) than your average cardboard box, but the concept is the same. It’s made by

sandwiching paper over a corrugated middle. Heavy automotive parts are often shipped in

heavy- duty cardboard boxes, and you can buy the cardboard new.

• Laminated composite materials include foamboard, which is a piece of plastic foam inside

two sheets of heavy paper. Other kinds of laminated composite sheets may use a combina-

tion of wood, paper, plastic, even thin metal.

• Corrugated plastic is a favorite among sign makers. They use sheets of it to make light-

weight (and very affordable) indoor and outdoor signs. These look like cardboard, as in

Figure 5-3, but they’re entirely made of plastic.

In Review: Selecting the Right Material

Let’s review the four main construction materials for building robots and compare their good

and bad sides.

Material Pros Cons

Wood Universally available; reasonably low Not as strong as plastic or metal; can

cost; easy to work with using ordinary warp with moisture (should be painted

shop tools; hardwood plywoods or sealed); cracks and splinters under

(recommended wood for most robot stress

bases) very sturdy and strong

05-chapter-5.indd 52 4/21/11 11:43 AM