Page 140 - Robot Builders Source Book - Gordon McComb

P. 140

4.2 Camshafts 129

For the central mechanism, where e = 0, we obtain a simpler expression for (4.23), i.e.:

or

The larger the pressure angle a, the lower the efficiency of the mechanism. When

this angle reaches a critical value, the mechanism can jam. The critical value of the

pressure angle depends on the friction conditions of the follower in its guides, on the

geometry of the guides, on the design of the follower (a flat follower always yields a = 0

but causes other restrictions), and on the geometry of the mechanism. To reduce the

pressure angle, we must analyze Expressions (4.23) and (4.24). It follows from them

that the pressure angle decreases as:

1. The value of a or r 0 increases;

2. The IT(0) function that describes the slope of the profile decreases.

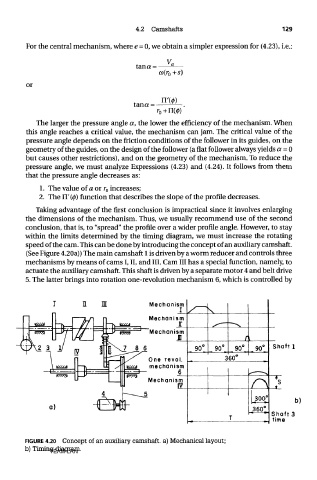

Taking advantage of the first conclusion is impractical since it involves enlarging

the dimensions of the mechanism. Thus, we usually recommend use of the second

conclusion, that is, to "spread" the profile over a wider profile angle. However, to stay

within the limits determined by the timing diagram, we must increase the rotating

speed of the cam. This can be done by introducing the concept of an auxiliary camshaft.

(See Figure 4.20a)) The main camshaft 1 is driven by a worm reducer and controls three

mechanisms by means of cams I, II, and III. Cam III has a special function, namely, to

actuate the auxiliary camshaft. This shaft is driven by a separate motor 4 and belt drive

5. The latter brings into rotation one-revolution mechanism 6, which is controlled by

FIGURE 4.20 Concept of an auxiliary camshaft, a) Mechanical layout;

b) Timing diagram.

TEAM LRN