Page 154 - Robot Builders Source Book - Gordon McComb

P. 154

142 Kinematics and Control of Automatic Machines

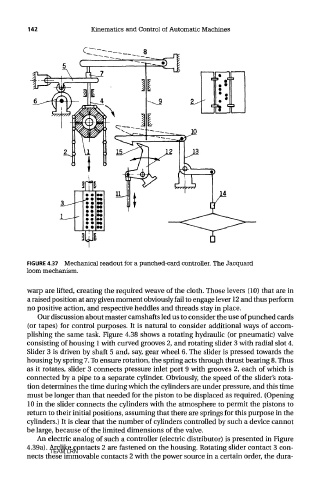

FIGURE 4.37 Mechanical readout for a punched-card controller. The Jacquard

loom mechanism.

warp are lifted, creating the required weave of the cloth. Those levers (10) that are in

a raised position at any given moment obviously fail to engage lever 12 and thus perform

no positive action, and respective heddles and threads stay in place.

Our discussion about master camshafts led us to consider the use of punched cards

(or tapes) for control purposes. It is natural to consider additional ways of accom-

plishing the same task. Figure 4.38 shows a rotating hydraulic (or pneumatic) valve

consisting of housing 1 with curved grooves 2, and rotating slider 3 with radial slot 4.

Slider 3 is driven by shaft 5 and, say, gear wheel 6. The slider is pressed towards the

housing by spring 7. To ensure rotation, the spring acts through thrust bearing 8. Thus

as it rotates, slider 3 connects pressure inlet port 9 with grooves 2, each of which is

connected by a pipe to a separate cylinder. Obviously, the speed of the slider's rota-

tion determines the time during which the cylinders are under pressure, and this time

must be longer than that needed for the piston to be displaced as required. (Opening

10 in the slider connects the cylinders with the atmosphere to permit the pistons to

return to their initial positions, assuming that there are springs for this purpose in the

cylinders.) It is clear that the number of cylinders controlled by such a device cannot

be large, because of the limited dimensions of the valve.

An electric analog of such a controller (electric distributor) is presented in Figure

4.39a). Arclike contacts 2 are fastened on the housing. Rotating slider contact 3 con-

TEAM LRN

nects these immovable contacts 2 with the power source in a certain order, the dura-