Page 271 - Robot Builders Source Book - Gordon McComb

P. 271

7.7 Passive Orientation 259

7.7 Passive Orientation

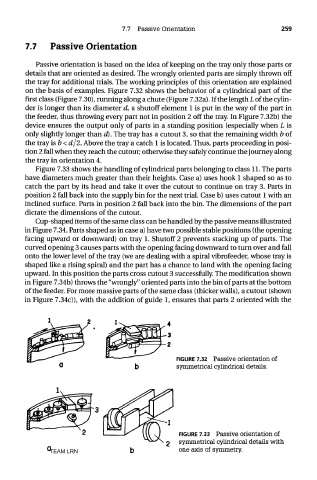

Passive orientation is based on the idea of keeping on the tray only those parts or

details that are oriented as desired. The wrongly oriented parts are simply thrown off

the tray for additional trials. The working principles of this orientation are explained

on the basis of examples. Figure 7.32 shows the behavior of a cylindrical part of the

first class (Figure 7.30), running along a chute (Figure 7.32a). If the length L of the cylin-

der is longer than its diameter d, a shutoff element 1 is put in the way of the part in

the feeder, thus throwing every part not in position 2 off the tray. In Figure 7.32b) the

device ensures the output only of parts in a standing position (especially when L is

only slightly longer than d). The tray has a cutout 3, so that the remaining width b of

the tray is b < d/2. Above the tray a catch 1 is located. Thus, parts proceeding in posi-

tion 2 fall when they reach the cutout; otherwise they safely continue the journey along

the tray in orientation 4.

Figure 7.33 shows the handling of cylindrical parts belonging to class 11. The parts

have diameters much greater than their heights. Case a) uses hook 1 shaped so as to

catch the part by its head and take it over the cutout to continue on tray 3. Parts in

position 2 fall back into the supply bin for the next trial. Case b) uses cutout 1 with an

inclined surface. Parts in position 2 fall back into the bin. The dimensions of the part

dictate the dimensions of the cutout.

Cup-shaped items of the same class can be handled by the passive means illustrated

in Figure 7.34. Parts shaped as in case a) have two possible stable positions (the opening

facing upward or downward) on tray 1. Shutoff 2 prevents stacking up of parts. The

curved opening 3 causes parts with the opening facing downward to turn over and fall

onto the lower level of the tray (we are dealing with a spiral vibrofeeder, whose tray is

shaped like a rising spiral) and the part has a chance to land with the opening facing

upward. In this position the parts cross cutout 3 successfully. The modification shown

in Figure 7.34b) throws the "wrongly" oriented parts into the bin of parts at the bottom

of the feeder. For more massive parts of the same class (thicker walls), a cutout (shown

in Figure 7.34c)), with the addition of guide 1, ensures that parts 2 oriented with the

FIGURE 7.32 Passive orientation of

symmetrical cylindrical details.

FIGURE 7.33 Passive orientation of

symmetrical cylindrical details with

TEAM LRN one axis of symmetry.