Page 23 - Robotics Designing the Mechanisms for Automated Machinery

P. 23

12 Introduction: Brief Historical Review and Main Definitions

• The nature of the optimal conceptual solution for achieving a particular goal;

• The type of tools or organs to be created for handling the subject under

processing;

• The means of establishing the mechanical displacements, trajectories, and

movements of the tools;

• The ways of providing the required rate of motion;

• The means of ensuring the required accuracy or, in other words, how not to

exceed the allowed deviation in the motion of tools or other elements.

1.3 Manipulators

Let us return here to the definition of a manipulator, as given in Section 1.1. A manip-

ulator may be defined as "a mechanism, usually consisting of a series of segments,

jointed or sliding relative to one another, for the purpose of grasping and moving

objects usually in several degrees of freedom. It may be remotely controlled by a com-

puter or by a human" [2]. It follows from this definition that a manipulator may belong

to systems of type 1 or 4, as described in Section 1.2, and are therefore not on a level

of complexity usually accepted for robots. We must therefore distinguish between man-

ually activated and automatically activated manipulators.

Manually activated manipulators were created to enable man to work under harmful

conditions such as in radioactive, extremely hot or cold, or poisonous environments,

under vacuum, or at high pressures. The development of nuclear science and its appli-

cations led to a proliferation in the creation of devices of this sort. One of the first such

manipulators was designed by Goertz at the Argonne National Laboratory in the U.S.A.

Such devices consist of two "arms," a control arm and a serving arm. The connection

between the arms provides the serving arm with the means of duplicating, at a distance,

the action of the control arm, and these devices are sometimes called teleoperators.

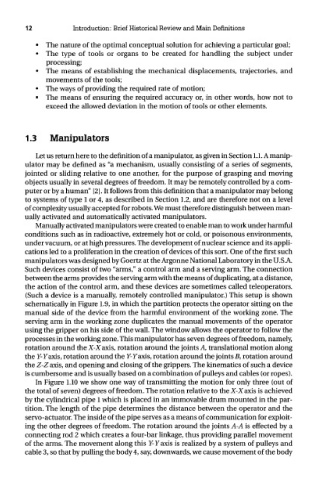

(Such a device is a manually, remotely controlled manipulator.) This setup is shown

schematically in Figure 1.9, in which the partition protects the operator sitting on the

manual side of the device from the harmful environment of the working zone. The

serving arm in the working zone duplicates the manual movements of the operator

using the gripper on his side of the wall. The window allows the operator to follow the

processes in the working zone. This manipulator has seven degrees of freedom, namely,

rotation around the X-X axis, rotation around the joints A, translational motion along

the F-Faxis, rotation around the F-Faxis, rotation around the joints B, rotation around

the Z-Zaxis, and opening and closing of the grippers. The kinematics of such a device

is cumbersome and is usually based on a combination of pulleys and cables (or ropes).

In Figure 1.10 we show one way of transmitting the motion for only three (out of

the total of seven) degrees of freedom. The rotation relative to the X-X axis is achieved

by the cylindrical pipe 1 which is placed in an immovable drum mounted in the par-

tition. The length of the pipe determines the distance between the operator and the

servo-actuator. The inside of the pipe serves as a means of communication for exploit-

ing the other degrees of freedom. The rotation around the joints A-A is effected by a

connecting rod 2 which creates a four-bar linkage, thus providing parallel movement

of the arms. The movement along this FFaxis is realized by a system of pulleys and

cable 3, so that by pulling the body 4, say, downwards, we cause movement of the body