Page 28 - Robotics Designing the Mechanisms for Automated Machinery

P. 28

1.3 Manipulators 17

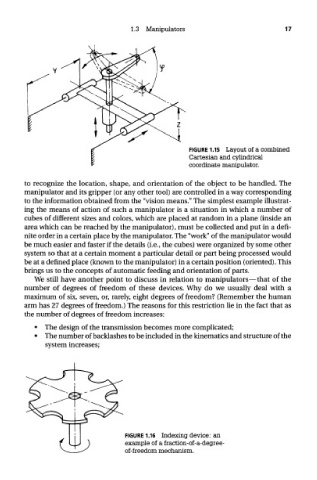

FIGURE 1.15 Layout of a combined

Cartesian and cylindrical

coordinate manipulator.

to recognize the location, shape, and orientation of the object to be handled. The

manipulator and its gripper (or any other tool) are controlled in a way corresponding

to the information obtained from the "vision means." The simplest example illustrat-

ing the means of action of such a manipulator is a situation in which a number of

cubes of different sizes and colors, which are placed at random in a plane (inside an

area which can be reached by the manipulator), must be collected and put in a defi-

nite order in a certain place by the manipulator. The "work" of the manipulator would

be much easier and faster if the details (i.e., the cubes) were organized by some other

system so that at a certain moment a particular detail or part being processed would

be at a defined place (known to the manipulator) in a certain position (oriented). This

brings us to the concepts of automatic feeding and orientation of parts.

We still have another point to discuss in relation to manipulators—that of the

number of degrees of freedom of these devices. Why do we usually deal with a

maximum of six, seven, or, rarely, eight degrees of freedom? (Remember the human

arm has 27 degrees of freedom.) The reasons for this restriction lie in the fact that as

the number of degrees of freedom increases:

• The design of the transmission becomes more complicated;

• The number of backlashes to be included in the kinematics and structure of the

system increases;

FIGURE 1.16 Indexing device: an

example of a fraction-of-a-degree-

of-freedom mechanism.