Page 36 - Robotics Designing the Mechanisms for Automated Machinery

P. 36

1.4 Structure of Automatic Industrial Systems 25

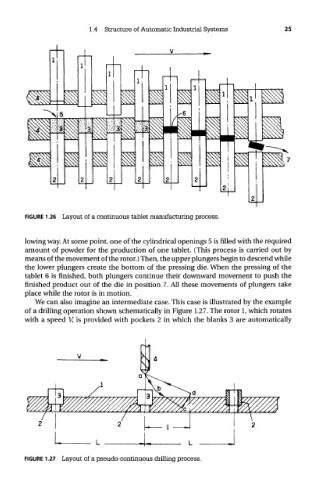

FIGURE 1.26 Layout of a continuous tablet manufacturing process.

lowing way. At some point, one of the cylindrical openings 5 is filled with the required

amount of powder for the production of one tablet. (This process is carried out by

means of the movement of the rotor.) Then, the upper plungers begin to descend while

the lower plungers create the bottom of the pressing die. When the pressing of the

tablet 6 is finished, both plungers continue their downward movement to push the

finished product out of the die in position 7. All these movements of plungers take

place while the rotor is in motion.

We can also imagine an intermediate case. This case is illustrated by the example

of a drilling operation shown schematically in Figure 1.27. The rotor 1, which rotates

with a speed V, is provided with pockets 2 in which the blanks 3 are automatically

FIGURE 1.27 Layout of a pseudo-continuous drilling process.