Page 193 - Robots Androids and Animatrons : 12 Incredible Projects You Can Build

P. 193

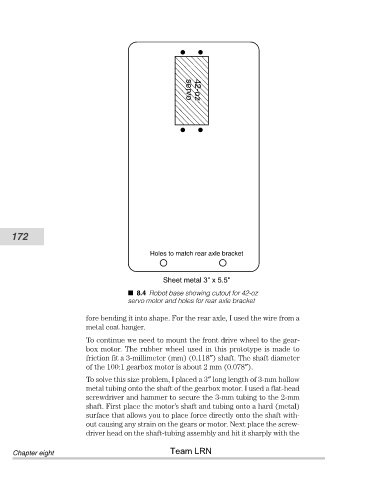

172 servo 42-oz

Holes to match rear axle bracket

Sheet metal 3" x 5.5"

8.4 Robot base showing cutout for 42-oz

servo motor and holes for rear axle bracket

fore bending it into shape. For the rear axle, I used the wire from a

metal coat hanger.

To continue we need to mount the front drive wheel to the gear-

box motor. The rubber wheel used in this prototype is made to

friction fit a 3-millimeter (mm) (0.118″) shaft. The shaft diameter

of the 100:1 gearbox motor is about 2 mm (0.078″).

To solve this size problem, I placed a 3″ long length of 3-mm hollow

metal tubing onto the shaft of the gearbox motor. I used a flat-head

screwdriver and hammer to secure the 3-mm tubing to the 2-mm

shaft. First place the motor’s shaft and tubing onto a hard (metal)

surface that allows you to place force directly onto the shaft with-

out causing any strain on the gears or motor. Next place the screw-

driver head on the shaft-tubing assembly and hit it sharply with the

Team LRN

Chapter eight