Page 54 - Robots Androids and Animatrons : 12 Incredible Projects You Can Build

P. 54

In general

Most robotists use alkaline batteries when primary batteries are

called for and NiCd batteries when secondary batteries are needed.

Building a NiCd battery charger

NiCd battery chargers are inexpensive. Typically it is not worth

the time and effort to build a stand-alone charger for common-size

batteries such as AAA, AA, C, D, and 9V. However, if one wishes to

incorporate a built-in charger for a robot, then knowing how to build

a custom battery charger is important. While most inexpensive

chargers will charge batteries only at the C/10 rate, even after the

batteries have received a full charge (14 h), the charger we will

build will drop the current down to a C/30 rate after the batteries

are fully charged. This is the recommended procedure for charg-

ing NiCd batteries. This will help ensure a long service life to your

rechargeable battery.

The following information will allow you to design a system for

charging a custom NiCd battery pack.

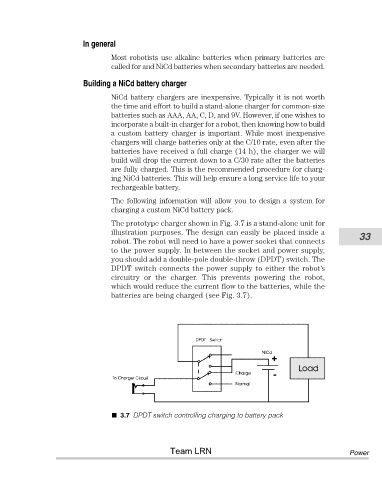

The prototype charger shown in Fig. 3.7 is a stand-alone unit for

illustration purposes. The design can easily be placed inside a 33

robot. The robot will need to have a power socket that connects

to the power supply. In between the socket and power supply,

you should add a double-pole double-throw (DPDT) switch. The

DPDT switch connects the power supply to either the robot’s

circuitry or the charger. This prevents powering the robot,

which would reduce the current flow to the batteries, while the

batteries are being charged (see Fig. 3.7).

3.7 DPDT switch controlling charging to battery pack

Team LRN Power