Page 361 - Rock Mechanics For Underground Mining

P. 361

MATERIALS AND TECHNIQUES

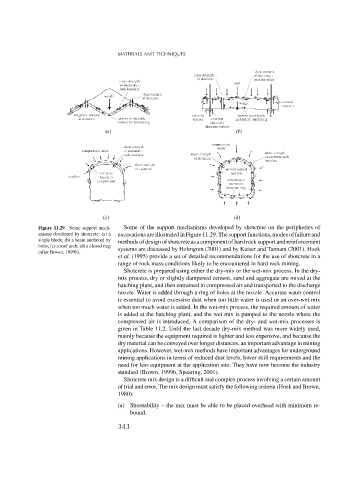

Figure 11.29 Some support mech- Some of the support mechanisms developed by shotcrete on the peripheries of

anisms developed by shotcrete: (a) a excavations are illustrated in Figure 11.29. The support functions, modes of failure and

single block; (b) a beam anchored by

methods of design of shotcrete as a component of hard rock support and reinforcement

bolts; (c) a roof arch; (d) a closed ring

systems are discussed by Holmgren (2001) and by Kaiser and Tannant (2001). Hoek

(after Brown, 1999b).

et al. (1995) provide a set of detailed recommendations for the use of shotcrete in a

range of rock mass conditions likely to be encountered in hard rock mining.

Shotcrete is prepared using either the dry-mix or the wet-mix process. In the dry-

mix process, dry or slightly dampened cement, sand and aggregate are mixed at the

batching plant, and then entrained in compressed air and transported to the discharge

nozzle. Water is added through a ring of holes at the nozzle. Accurate water control

is essential to avoid excessive dust when too little water is used or an over-wet mix

when too much water is added. In the wet-mix process, the required amount of water

is added at the batching plant, and the wet mix is pumped to the nozzle where the

compressed air is introduced. A comparison of the dry- and wet-mix processes is

given in Table 11.2. Until the last decade dry-mix method was more widely used,

mainly because the equipment required is lighter and less expensive, and because the

dry material can be conveyed over longer distances, an important advantage in mining

applications. However, wet-mix methods have important advantages for underground

mining applications in terms of reduced dust levels, lower skill requirements and the

need for less equipment at the application site. They have now become the industry

standard (Brown, 1999b, Spearing, 2001).

Shotcrete mix design is a difficult and complex process involving a certain amount

of trial and error. The mix design must satisfy the following criteria (Hoek and Brown,

1980):

(a) Shootability – the mix must be able to be placed overhead with minimum re-

bound.

343