Page 358 - Rock Mechanics For Underground Mining

P. 358

ROCK SUPPORT AND REINFORCEMENT

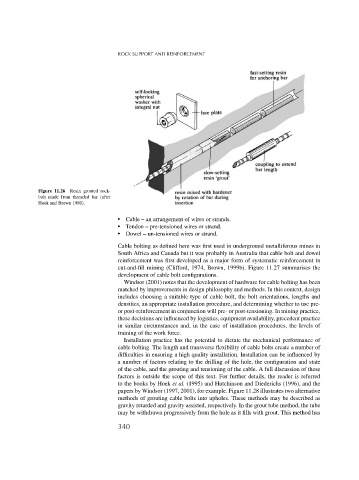

Figure 11.26 Resin grouted rock-

bolt made from threaded bar (after

Hoek and Brown 1980).

Cable – an arrangement of wires or strands.

Tendon – pre-tensioned wires or strand.

Dowel – un-tensioned wires or strand.

Cable bolting as defined here was first used in underground metalliferous mines in

South Africa and Canada but it was probably in Australia that cable bolt and dowel

reinforcement was first developed as a major form of systematic reinforcement in

cut-and-fill mining (Clifford, 1974, Brown, 1999b). Figure 11.27 summarises the

development of cable bolt configurations.

Windsor (2001) notes that the development of hardware for cable bolting has been

matched by improvements in design philosophy and methods. In this context, design

includes choosing a suitable type of cable bolt, the bolt orientations, lengths and

densities, an appropriate installation procedure, and determining whether to use pre-

or post-reinforcement in conjunction will pre- or post-tensioning. In mining practice,

these decisions are influenced by logistics, equipment availability, precedent practice

in similar circumstances and, in the case of installation procedures, the levels of

training of the work force.

Installation practice has the potential to dictate the mechanical performance of

cable bolting. The length and transverse flexibility of cable bolts create a number of

difficulties in ensuring a high quality installation. Installation can be influenced by

a number of factors relating to the drilling of the hole, the configuration and state

of the cable, and the grouting and tensioning of the cable. A full discussion of these

factors is outside the scope of this text. For further details, the reader is referred

to the books by Hoek et al. (1995) and Hutchinson and Diederichs (1996), and the

papers by Windsor (1997, 2001), for example. Figure 11.28 illustrates two alternative

methods of grouting cable bolts into upholes. These methods may be described as

gravity retarded and gravity assisted, respectively. In the grout tube method, the tube

may be withdrawn progressively from the hole as it fills with grout. This method has

340