Page 360 - Rock Mechanics For Underground Mining

P. 360

ROCK SUPPORT AND REINFORCEMENT

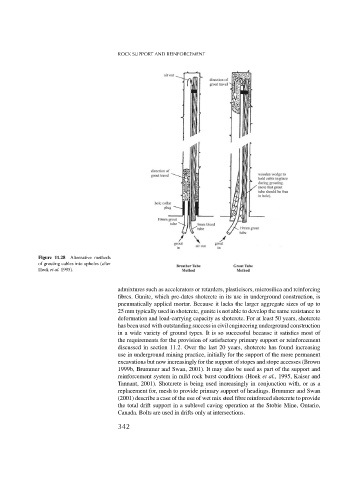

Figure 11.28 Alternative methods

of grouting cables into upholes (after

Hoek et al. 1995).

admixtures such as accelerators or retarders, plasticisers, microsilica and reinforcing

fibres. Gunite, which pre-dates shotcrete in its use in underground construction, is

pneumatically applied mortar. Because it lacks the larger aggregate sizes of up to

25 mm typically used in shotcrete, gunite is not able to develop the same resistance to

deformation and load-carrying capacity as shotcrete. For at least 50 years, shotcrete

has been used with outstanding success in civil engineering underground construction

in a wide variety of ground types. It is so successful because it satisfies most of

the requirements for the provision of satisfactory primary support or reinforcement

discussed in section 11.2. Over the last 20 years, shotcrete has found increasing

use in underground mining practice, initially for the support of the more permanent

excavations but now increasingly for the support of stopes and stope accesses (Brown

1999b, Brummer and Swan, 2001). It may also be used as part of the support and

reinforcement system in mild rock burst conditions (Hoek et al., 1995, Kaiser and

Tannant, 2001). Shotcrete is being used increasingly in conjunction with, or as a

replacement for, mesh to provide primary support of headings. Brummer and Swan

(2001) describe a case of the use of wet mix steel fibre reinforced shotcrete to provide

the total drift support in a sublevel caving operation at the Stobie Mine, Ontario,

Canada. Bolts are used in drifts only at intersections.

342