Page 445 - Rock Mechanics For Underground Mining

P. 445

BACKFILL APPLICATIONS IN OPEN AND BENCH STOPING

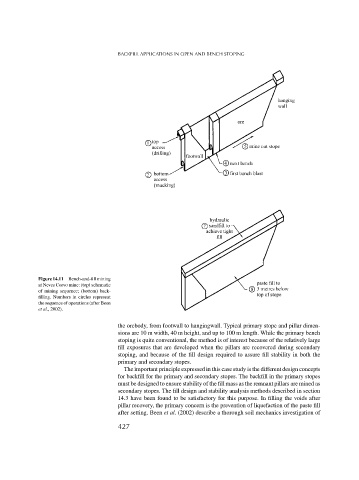

Figure 14.11 Bench-and-fill mining

at Neves Corvo mine: (top) schematic

of mining sequence; (bottom) back-

filling. Numbers in circles represent

the sequence of operations (after Been

et al., 2002).

the orebody, from footwall to hangingwall. Typical primary stope and pillar dimen-

sions are 10 m width, 40 m height, and up to 100 m length. While the primary bench

stoping is quite conventional, the method is of interest because of the relatively large

fill exposures that are developed when the pillars are recovered during secondary

stoping, and because of the fill design required to assure fill stability in both the

primary and secondary stopes.

The important principle expressed in this case study is the different design concepts

for backfill for the primary and secondary stopes. The backfill in the primary stopes

must be designed to ensure stability of the fill mass as the remnant pillars are mined as

secondary stopes. The fill design and stability analysis methods described in section

14.3 have been found to be satisfactory for this purpose. In filling the voids after

pillar recovery, the primary concern is the prevention of liquefaction of the paste fill

after setting. Been et al. (2002) describe a thorough soil mechanics investigation of

427