Page 158 - Rotating Machinery Pratical Solutions to Unbalance and Misalignment

P. 158

Rotating Machinery: Practical Solutions

Figure 8-24. Vertical Pump

3 4

2 1

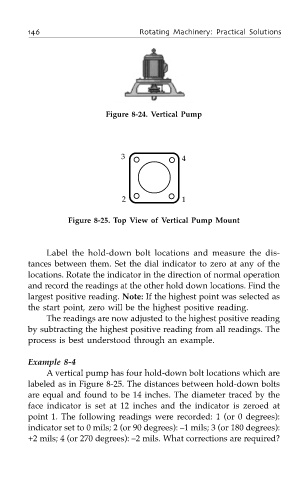

Figure 8-25. Top View of Vertical Pump Mount

Label the hold-down bolt locations and measure the dis-

tances between them. Set the dial indicator to zero at any of the

locations. Rotate the indicator in the direction of normal operation

and record the readings at the other hold down locations. Find the

largest positive reading. Note: If the highest point was selected as

the start point, zero will be the highest positive reading.

The readings are now adjusted to the highest positive reading

by subtracting the highest positive reading from all readings. The

process is best understood through an example.

Example 8-4

A vertical pump has four hold-down bolt locations which are

labeled as in Figure 8-25. The distances between hold-down bolts

are equal and found to be 14 inches. The diameter traced by the

face indicator is set at 12 inches and the indicator is zeroed at

point 1. The following readings were recorded: 1 (or 0 degrees):

indicator set to 0 mils; 2 (or 90 degrees): –1 mils; 3 (or 180 degrees):

+2 mils; 4 (or 270 degrees): –2 mils. What corrections are required?