Page 156 - Rotating Machinery Pratical Solutions to Unbalance and Misalignment

P. 156

Rotating Machinery: Practical Solutions

1 Inch drop

in 12 inches

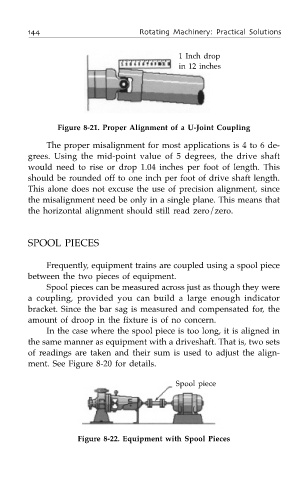

Figure 8-21. Proper Alignment of a U-Joint Coupling

The proper misalignment for most applications is 4 to 6 de-

grees. Using the mid-point value of 5 degrees, the drive shaft

would need to rise or drop 1.04 inches per foot of length. This

should be rounded off to one inch per foot of drive shaft length.

This alone does not excuse the use of precision alignment, since

the misalignment need be only in a single plane. This means that

the horizontal alignment should still read zero/zero.

SPOOL PIECES

Frequently, equipment trains are coupled using a spool piece

between the two pieces of equipment.

Spool pieces can be measured across just as though they were

a coupling, provided you can build a large enough indicator

bracket. Since the bar sag is measured and compensated for, the

amount of droop in the fixture is of no concern.

In the case where the spool piece is too long, it is aligned in

the same manner as equipment with a driveshaft. That is, two sets

of readings are taken and their sum is used to adjust the align-

ment. See Figure 8-20 for details.

Spool piece

Figure 8-22. Equipment with Spool Pieces