Page 295 - Semiconductor For Micro- and Nanotechnology An Introduction For Engineers

P. 295

Interacting Subsystems

dξ

dξ

V

θ

S

M M

θ B V

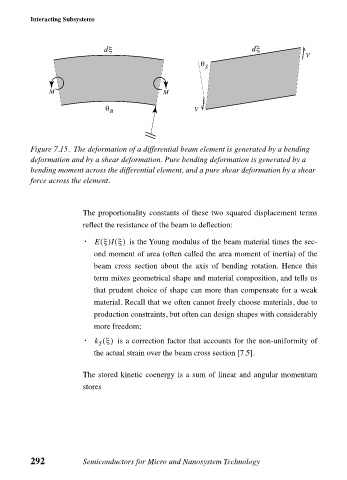

Figure 7.15. The deformation of a differential beam element is generated by a bending

deformation and by a shear deformation. Pure bending deformation is generated by a

bending moment across the differential element, and a pure shear deformation by a shear

force across the element.

The proportionality constants of these two squared displacement terms

reflect the resistance of the beam to deflection:

• E ξ()I ξ() is the Young modulus of the beam material times the sec-

ond moment of area (often called the area moment of inertia) of the

beam cross section about the axis of bending rotation. Hence this

term mixes geometrical shape and material composition, and tells us

that prudent choice of shape can more than compensate for a weak

material. Recall that we often cannot freely choose materials, due to

production constraints, but often can design shapes with considerably

more freedom;

• k ξ() is a correction factor that accounts for the non-uniformity of

T

the actual strain over the beam cross section [7.5].

The stored kinetic coenergy is a sum of linear and angular momentum

stores

292 Semiconductors for Micro and Nanosystem Technology