Page 258 - Semiconductor Manufacturing Handbook

P. 258

Geng(SMH)_CH17.qxd 04/04/2005 19:58 Page 17.13

CHEMICAL MECHANICAL POLISHING

CHEMICAL MECHANICAL POLISHING 17.13

Pressure

gauge

Pressure

P

gauge

P Flow

valve

Flow meter

Filtration

element

Heat

exchanger Permeate

Flow

valve

Pressure

P

gauge

Flow Valve

valve Feed

tank Drain

Centrifugal pump

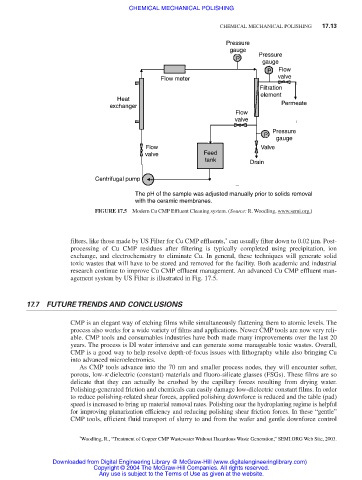

The pH of the sample was adjusted manually prior to solids removal

with the ceramic membranes.

FIGURE 17.5 Modern Cu CMP Effluent Cleaning system. (Source: R. Woodling, www.semi.org.)

*

filters, like those made by US Filter for Cu CMP effluents, can usually filter down to 0.02 µm. Post-

processing of Cu CMP residues after filtering is typically completed using precipitation, ion

exchange, and electrochemistry to eliminate Cu. In general, these techniques will generate solid

toxic wastes that will have to be stored and removed for the facility. Both academic and industrial

research continue to improve Cu CMP effluent management. An advanced Cu CMP effluent man-

agement system by US Filter is illustrated in Fig. 17.5.

17.7 FUTURE TRENDS AND CONCLUSIONS

CMP is an elegant way of etching films while simultaneously flattening them to atomic levels. The

process also works for a wide variety of films and applications. Newer CMP tools are now very reli-

able. CMP tools and consumables industries have both made many improvements over the last 20

years. The process is DI water intensive and can generate some manageable toxic wastes. Overall,

CMP is a good way to help resolve depth-of-focus issues with lithography while also bringing Cu

into advanced microelectronics.

As CMP tools advance into the 70 nm and smaller process nodes, they will encounter softer,

porous, low-k dielectric (constant) materials and fluoro-silicate glasses (FSGs). These films are so

delicate that they can actually be crushed by the capillary forces resulting from drying water.

Polishing-generated friction and chemicals can easily damage low-dielectric constant films. In order

to reduce polishing-related shear forces, applied polishing downforce is reduced and the table (pad)

speed is increased to bring up material removal rates. Polishing near the hydroplaning regime is helpful

for improving planarization efficiency and reducing polishing shear friction forces. In these “gentle”

CMP tools, efficient fluid transport of slurry to and from the wafer and gentle downforce control

* Woodling, R., “Treatment of Copper CMP Wastewater Without Hazardous Waste Generation,” SEMI.ORG Web Site, 2003.

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2004 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.