Page 106 - Sensors and Control Systems in Manufacturing

P. 106

Classification and Types of Sensors

2.6.2 Inductive Proximity Sensing Range 67

The sensing range of an inductive proximity sensor refers to the dis-

tance between the sensor face and the target. It also includes the shape

of the sensing field generated through the coil and core. Several

mechanical and environmental factors affect the sensing range, such

as those shown in the following table.

Mechanical Factors Environmental Factors

Core size Ambient temperature

Core shield Surrounding electrical conditions

Target material Surrounding mechanical conditions

Target size Variation between devices

Target shape

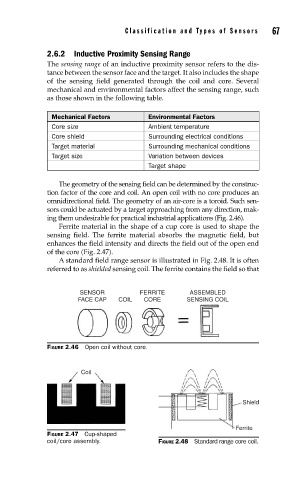

The geometry of the sensing field can be determined by the construc-

tion factor of the core and coil. An open coil with no core produces an

omnidirectional field. The geometry of an air-core is a toroid. Such sen-

sors could be actuated by a target approaching from any direction, mak-

ing them undesirable for practical industrial applications (Fig. 2.46).

Ferrite material in the shape of a cup core is used to shape the

sensing field. The ferrite material absorbs the magnetic field, but

enhances the field intensity and directs the field out of the open end

of the core (Fig. 2.47).

A standard field range sensor is illustrated in Fig. 2.48. It is often

referred to as shielded sensing coil. The ferrite contains the field so that

SENSOR FERRITE ASSEMBLED

FACE CAP COIL CORE SENSING COIL

FIGURE 2.46 Open coil without core.

Coil

Shield

Ferrite

FIGURE 2.47 Cup-shaped

coil/core assembly. FIGURE 2.48 Standard range core coil.