Page 110 - Sensors and Control Systems in Manufacturing

P. 110

Classification and Types of Sensors

Tubular, mm 71

Limit-Switch Pancake

Target Material Type Type 8 12 18 30

Steel (1020) 1.0 1.0 1.0 1.0 1.0 1.0

Stainless steel (400) 1.03 0.90 0.90 0.90 1.0 1.0

Stainless steel (300) 0.85 0.70 0.60 0.70 0.70 0.65

Brass 0.50 0.54 0.35 0.45 0.45 0.45

Aluminum 0.47 0.50 0.35 0.40 0.45 0.40

Copper 0.40 0.46 0.30 0.25 0.35 0.30

TABLE 2.6 Target Correction

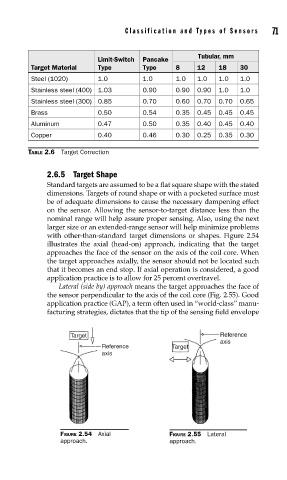

2.6.5 Target Shape

Standard targets are assumed to be a flat square shape with the stated

dimensions. Targets of round shape or with a pocketed surface must

be of adequate dimensions to cause the necessary dampening effect

on the sensor. Allowing the sensor-to-target distance less than the

nominal range will help assure proper sensing. Also, using the next

larger size or an extended-range sensor will help minimize problems

with other-than-standard target dimensions or shapes. Figure 2.54

illustrates the axial (head-on) approach, indicating that the target

approaches the face of the sensor on the axis of the coil core. When

the target approaches axially, the sensor should not be located such

that it becomes an end stop. If axial operation is considered, a good

application practice is to allow for 25 percent overtravel.

Lateral (side by) approach means the target approaches the face of

the sensor perpendicular to the axis of the coil core (Fig. 2.55). Good

application practice (GAP), a term often used in “world-class” manu-

facturing strategies, dictates that the tip of the sensing field envelope

Target Reference

axis

Reference Target

axis

FIGURE 2.54 Axial FIGURE 2.55 Lateral

approach. approach.