Page 181 - Sensors and Control Systems in Manufacturing

P. 181

142

T h ree

Cha p te r

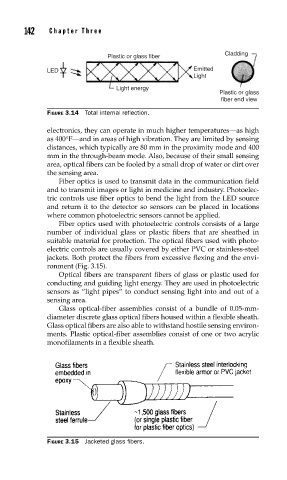

Cladding

Plastic or glass fiber

LED Emitted

Light

Light energy

Plastic or glass

fiber end view

FIGURE 3.14 Total internal refl ection.

electronics, they can operate in much higher temperatures—as high

as 400°F—and in areas of high vibration. They are limited by sensing

distances, which typically are 80 mm in the proximity mode and 400

mm in the through-beam mode. Also, because of their small sensing

area, optical fibers can be fooled by a small drop of water or dirt over

the sensing area.

Fiber optics is used to transmit data in the communication field

and to transmit images or light in medicine and industry. Photoelec-

tric controls use fiber optics to bend the light from the LED source

and return it to the detector so sensors can be placed in locations

where common photoelectric sensors cannot be applied.

Fiber optics used with photoelectric controls consists of a large

number of individual glass or plastic fibers that are sheathed in

suitable material for protection. The optical fibers used with photo-

electric controls are usually covered by either PVC or stainless-steel

jackets. Both protect the fibers from excessive flexing and the envi-

ronment (Fig. 3.15).

Optical fibers are transparent fibers of glass or plastic used for

conducting and guiding light energy. They are used in photoelectric

sensors as “light pipes” to conduct sensing light into and out of a

sensing area.

Glass optical-fiber assemblies consist of a bundle of 0.05-mm-

diameter discrete glass optical fibers housed within a flexible sheath.

Glass optical fibers are also able to withstand hostile sensing environ-

ments. Plastic optical-fiber assemblies consist of one or two acrylic

monofilaments in a flexible sheath.

FIGURE 3.15 Jacketed glass fi bers.