Page 185 - Sensors and Control Systems in Manufacturing

P. 185

146

Cha p te r

T h ree

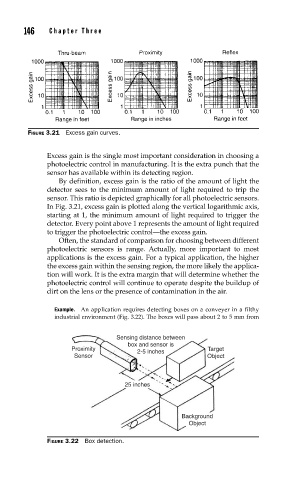

FIGURE 3.21 Excess gain curves.

Excess gain is the single most important consideration in choosing a

photoelectric control in manufacturing. It is the extra punch that the

sensor has available within its detecting region.

By definition, excess gain is the ratio of the amount of light the

detector sees to the minimum amount of light required to trip the

sensor. This ratio is depicted graphically for all photoelectric sensors.

In Fig. 3.21, excess gain is plotted along the vertical logarithmic axis,

starting at 1, the minimum amount of light required to trigger the

detector. Every point above 1 represents the amount of light required

to trigger the photoelectric control—the excess gain.

Often, the standard of comparison for choosing between different

photoelectric sensors is range. Actually, more important to most

applications is the excess gain. For a typical application, the higher

the excess gain within the sensing region, the more likely the applica-

tion will work. It is the extra margin that will determine whether the

photoelectric control will continue to operate despite the buildup of

dirt on the lens or the presence of contamination in the air.

Example. An application requires detecting boxes on a conveyer in a filthy

industrial environment (Fig. 3.22). The boxes will pass about 2 to 5 mm from

Sensing distance between

box and sensor is

Proximity 2-5 inches Target

Sensor Object

25 inches

Background

Object

FIGURE 3.22 Box detection.