Page 279 - Sensors and Control Systems in Manufacturing

P. 279

238

Cha p te r

F i v e

Input and output for engineering management include exchang-

ing designs and descriptions with engineering design; reviewing

product data, routings, and schedules with production planning; and

accepting engineering change requests from plant operations.

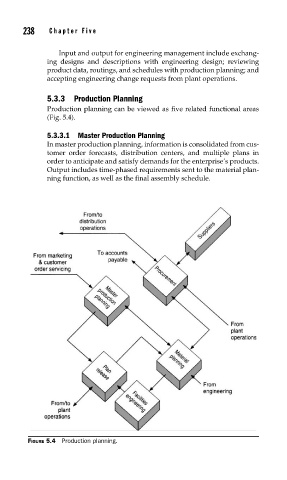

5.3.3 Production Planning

Production planning can be viewed as five related functional areas

(Fig. 5.4).

5.3.3.1 Master Production Planning

In master production planning, information is consolidated from cus-

tomer order forecasts, distribution centers, and multiple plans in

order to anticipate and satisfy demands for the enterprise’s products.

Output includes time-phased requirements sent to the material plan-

ning function, as well as the final assembly schedule.

FIGURE 5.4 Production planning.