Page 284 - Sensors and Control Systems in Manufacturing

P. 284

The Role of Sensors and Contr ol Technology in CIM

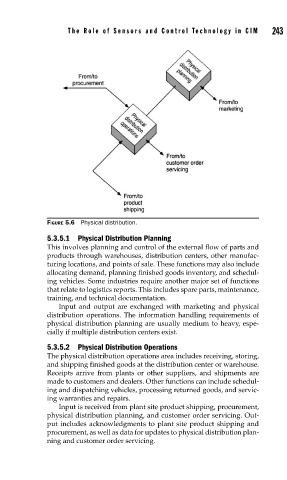

FIGURE 5.6 Physical distribution. 243

5.3.5.1 Physical Distribution Planning

This involves planning and control of the external flow of parts and

products through warehouses, distribution centers, other manufac-

turing locations, and points of sale. These functions may also include

allocating demand, planning finished goods inventory, and schedul-

ing vehicles. Some industries require another major set of functions

that relate to logistics reports. This includes spare parts, maintenance,

training, and technical documentation.

Input and output are exchanged with marketing and physical

distribution operations. The information handling requirements of

physical distribution planning are usually medium to heavy, espe-

cially if multiple distribution centers exist.

5.3.5.2 Physical Distribution Operations

The physical distribution operations area includes receiving, storing,

and shipping finished goods at the distribution center or warehouse.

Receipts arrive from plants or other suppliers, and shipments are

made to customers and dealers. Other functions can include schedul-

ing and dispatching vehicles, processing returned goods, and servic-

ing warranties and repairs.

Input is received from plant site product shipping, procurement,

physical distribution planning, and customer order servicing. Out-

put includes acknowledgments to plant site product shipping and

procurement, as well as data for updates to physical distribution plan-

ning and customer order servicing.