Page 288 - Sensors and Control Systems in Manufacturing

P. 288

The Role of Sensors and Contr ol Technology in CIM

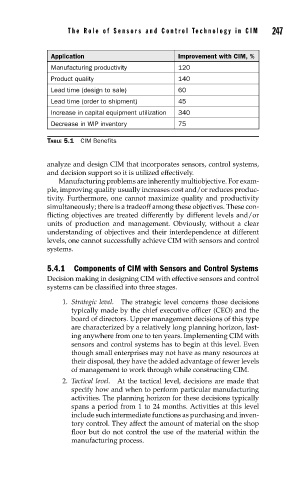

Application Improvement with CIM, % 247

Manufacturing productivity 120

Product quality 140

Lead time (design to sale) 60

Lead time (order to shipment) 45

Increase in capital equipment utilization 340

Decrease in WIP inventory 75

TABLE 5.1 CIM Benefits

analyze and design CIM that incorporates sensors, control systems,

and decision support so it is utilized effectively.

Manufacturing problems are inherently multiobjective. For exam-

ple, improving quality usually increases cost and/or reduces produc-

tivity. Furthermore, one cannot maximize quality and productivity

simultaneously; there is a tradeoff among these objectives. These con-

flicting objectives are treated differently by different levels and/or

units of production and management. Obviously, without a clear

understanding of objectives and their interdependence at different

levels, one cannot successfully achieve CIM with sensors and control

systems.

5.4.1 Components of CIM with Sensors and Control Systems

Decision making in designing CIM with effective sensors and control

systems can be classified into three stages.

1. Strategic level. The strategic level concerns those decisions

typically made by the chief executive officer (CEO) and the

board of directors. Upper management decisions of this type

are characterized by a relatively long planning horizon, last-

ing anywhere from one to ten years. Implementing CIM with

sensors and control systems has to begin at this level. Even

though small enterprises may not have as many resources at

their disposal, they have the added advantage of fewer levels

of management to work through while constructing CIM.

2. Tactical level. At the tactical level, decisions are made that

specify how and when to perform particular manufacturing

activities. The planning horizon for these decisions typically

spans a period from 1 to 24 months. Activities at this level

include such intermediate functions as purchasing and inven-

tory control. They affect the amount of material on the shop

floor but do not control the use of the material within the

manufacturing process.