Page 281 - Sensors and Control Systems in Manufacturing

P. 281

240

F i v e

Cha p te r

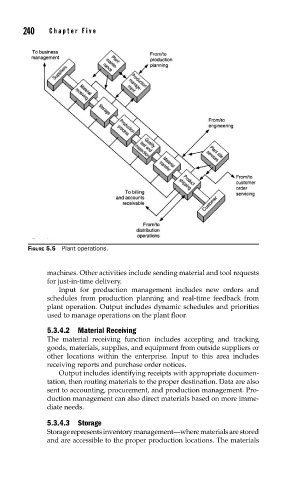

FIGURE 5.5 Plant operations.

machines. Other activities include sending material and tool requests

for just-in-time delivery.

Input for production management includes new orders and

schedules from production planning and real-time feedback from

plant operation. Output includes dynamic schedules and priorities

used to manage operations on the plant floor.

5.3.4.2 Material Receiving

The material receiving function includes accepting and tracking

goods, materials, supplies, and equipment from outside suppliers or

other locations within the enterprise. Input to this area includes

receiving reports and purchase order notices.

Output includes identifying receipts with appropriate documen-

tation, then routing materials to the proper destination. Data are also

sent to accounting, procurement, and production management. Pro-

duction management can also direct materials based on more imme-

diate needs.

5.3.4.3 Storage

Storage represents inventory management—where materials are stored

and are accessible to the proper production locations. The materials