Page 404 - Sensors and Control Systems in Manufacturing

P. 404

358

Cha p te r

Se v e n

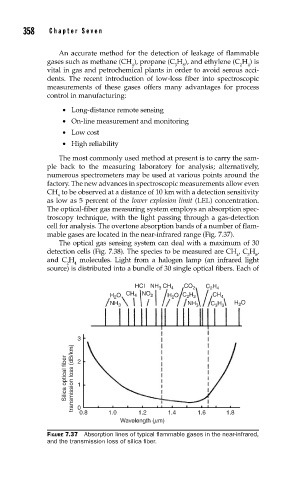

An accurate method for the detection of leakage of flammable

gases such as methane (CH ), propane (C H ), and ethylene (C H ) is

4 3 8 2 4

vital in gas and petrochemical plants in order to avoid serous acci-

dents. The recent introduction of low-loss fiber into spectroscopic

measurements of these gases offers many advantages for process

control in manufacturing:

• Long-distance remote sensing

• On-line measurement and monitoring

• Low cost

• High reliability

The most commonly used method at present is to carry the sam-

ple back to the measuring laboratory for analysis; alternatively,

numerous spectrometers may be used at various points around the

factory. The new advances in spectroscopic measurements allow even

CH to be observed at a distance of 10 km with a detection sensitivity

4

as low as 5 percent of the lower explosion limit (LEL) concentration.

The optical-fiber gas measuring system employs an absorption spec-

troscopy technique, with the light passing through a gas-detection

cell for analysis. The overtone absorption bands of a number of flam-

mable gases are located in the near-infrared range (Fig. 7.37).

The optical gas sensing system can deal with a maximum of 30

detection cells (Fig. 7.38). The species to be measured are CH , C H ,

4 3 8

and C H molecules. Light from a halogen lamp (an infrared light

2 4

source) is distributed into a bundle of 30 single optical fibers. Each of

HCI NH CH 4 CO 2 C H

3

2 4

H O CH 4 NO 2 H O C H CH 4

2 2

2

2

NH 3 NH 3 C H H O

2

3 3

3

Silica optical fiber transmission loss (dB/km) 2

1

0

0.8 1.0 1.2 1.4 1.6 1.8

Wavelength (mm)

FIGURE 7.37 Absorption lines of typical fl ammable gases in the near-infrared,

and the transmission loss of silica fi ber.