Page 419 - Sensors and Control Systems in Manufacturing

P. 419

Industrial Sensors and Contr ol

Light source 373

Flexible tube

Image fiber

Light guide

Objective lens

Eyepiece

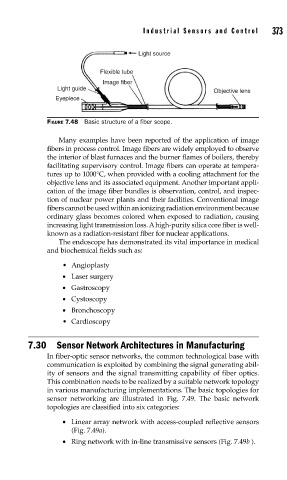

FIGURE 7.48 Basic structure of a fi ber scope.

Many examples have been reported of the application of image

fibers in process control. Image fibers are widely employed to observe

the interior of blast furnaces and the burner flames of boilers, thereby

facilitating supervisory control. Image fibers can operate at tempera-

tures up to 1000°C, when provided with a cooling attachment for the

objective lens and its associated equipment. Another important appli-

cation of the image fiber bundles is observation, control, and inspec-

tion of nuclear power plants and their facilities. Conventional image

fibers cannot be used within an ionizing radiation environment because

ordinary glass becomes colored when exposed to radiation, causing

increasing light transmission loss. A high-purity silica core fiber is well-

known as a radiation-resistant fiber for nuclear applications.

The endoscope has demonstrated its vital importance in medical

and biochemical fields such as:

• Angioplasty

• Laser surgery

• Gastroscopy

• Cystoscopy

• Bronchoscopy

• Cardioscopy

7.30 Sensor Network Architectures in Manufacturing

In fiber-optic sensor networks, the common technological base with

communication is exploited by combining the signal generating abil-

ity of sensors and the signal transmitting capability of fiber optics.

This combination needs to be realized by a suitable network topology

in various manufacturing implementations. The basic topologies for

sensor networking are illustrated in Fig. 7.49. The basic network

topologies are classified into six categories:

• Linear array network with access-coupled reflective sensors

(Fig. 7.49a).

• Ring network with in-line transmissive sensors (Fig. 7.49b ).