Page 414 - Sensors and Control Systems in Manufacturing

P. 414

368

Se v e n

Cha p te r

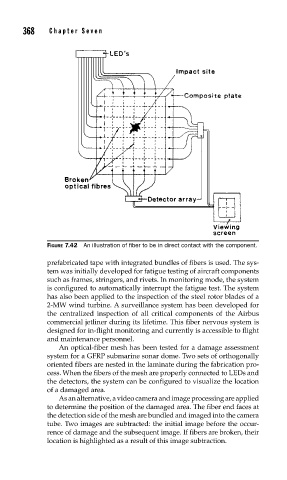

FIGURE 7.42 An illustration of fi ber to be in direct contact with the component.

prefabricated tape with integrated bundles of fibers is used. The sys-

tem was initially developed for fatigue testing of aircraft components

such as frames, stringers, and rivets. In monitoring mode, the system

is configured to automatically interrupt the fatigue test. The system

has also been applied to the inspection of the steel rotor blades of a

2-MW wind turbine. A surveillance system has been developed for

the centralized inspection of all critical components of the Airbus

commercial jetliner during its lifetime. This fiber nervous system is

designed for in-flight monitoring and currently is accessible to flight

and maintenance personnel.

An optical-fiber mesh has been tested for a damage assessment

system for a GFRP submarine sonar dome. Two sets of orthogonally

oriented fibers are nested in the laminate during the fabrication pro-

cess. When the fibers of the mesh are properly connected to LEDs and

the detectors, the system can be configured to visualize the location

of a damaged area.

As an alternative, a video camera and image processing are applied

to determine the position of the damaged area. The fiber end faces at

the detection side of the mesh are bundled and imaged into the camera

tube. Two images are subtracted: the initial image before the occur-

rence of damage and the subsequent image. If fibers are broken, their

location is highlighted as a result of this image subtraction.