Page 524 - Sensors and Control Systems in Manufacturing

P. 524

Communications

Conveyor belt 477

Motor

Counting pulses

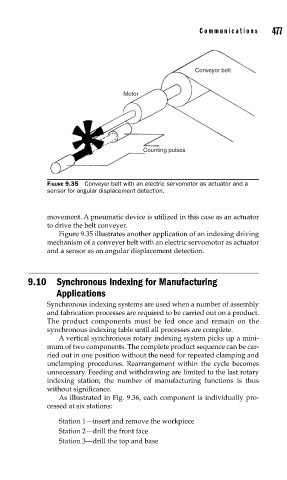

FIGURE 9.35 Conveyer belt with an electric servomotor as actuator and a

sensor for angular displacement detection.

movement. A pneumatic device is utilized in this case as an actuator

to drive the belt conveyer.

Figure 9.35 illustrates another application of an indexing driving

mechanism of a conveyer belt with an electric servomotor as actuator

and a sensor as an angular displacement detection.

9.10 Synchronous Indexing for Manufacturing

Applications

Synchronous indexing systems are used when a number of assembly

and fabrication processes are required to be carried out on a product.

The product components must be fed once and remain on the

synchronous indexing table until all processes are complete.

A vertical synchronous rotary indexing system picks up a mini-

mum of two components. The complete product sequence can be car-

ried out in one position without the need for repeated clamping and

unclamping procedures. Rearrangement within the cycle becomes

unnecessary. Feeding and withdrawing are limited to the last rotary

indexing station; the number of manufacturing functions is thus

without significance.

As illustrated in Fig. 9.36, each component is individually pro-

cessed at six stations:

Station 1—insert and remove the workpiece

Station 2—drill the front face

Station 3—drill the top and base