Page 522 - Sensors and Control Systems in Manufacturing

P. 522

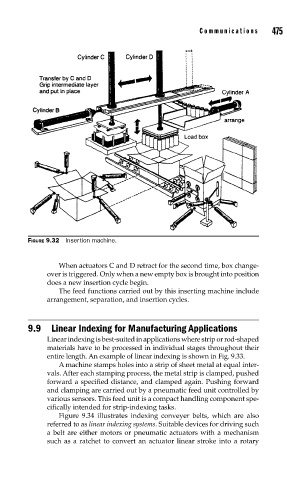

FIGURE 9.32 Insertion machine. Communications 475

When actuators C and D retract for the second time, box change-

over is triggered. Only when a new empty box is brought into position

does a new insertion cycle begin.

The feed functions carried out by this inserting machine include

arrangement, separation, and insertion cycles.

9.9 Linear Indexing for Manufacturing Applications

Linear indexing is best-suited in applications where strip or rod-shaped

materials have to be processed in individual stages throughout their

entire length. An example of linear indexing is shown in Fig. 9.33.

A machine stamps holes into a strip of sheet metal at equal inter-

vals. After each stamping process, the metal strip is clamped, pushed

forward a specified distance, and clamped again. Pushing forward

and clamping are carried out by a pneumatic feed unit controlled by

various sensors. This feed unit is a compact handling component spe-

cifically intended for strip-indexing tasks.

Figure 9.34 illustrates indexing conveyer belts, which are also

referred to as linear indexing systems. Suitable devices for driving such

a belt are either motors or pneumatic actuators with a mechanism

such as a ratchet to convert an actuator linear stroke into a rotary