Page 520 - Sensors and Control Systems in Manufacturing

P. 520

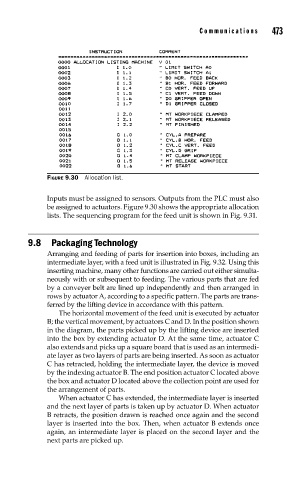

FIGURE 9.30 Allocation list. Communications 473

Inputs must be assigned to sensors. Outputs from the PLC must also

be assigned to actuators. Figure 9.30 shows the appropriate allocation

lists. The sequencing program for the feed unit is shown in Fig. 9.31.

9.8 Packaging Technology

Arranging and feeding of parts for insertion into boxes, including an

intermediate layer, with a feed unit is illustrated in Fig. 9.32. Using this

inserting machine, many other functions are carried out either simulta-

neously with or subsequent to feeding. The various parts that are fed

by a conveyer belt are lined up independently and then arranged in

rows by actuator A, according to a specific pattern. The parts are trans-

ferred by the lifting device in accordance with this pattern.

The horizontal movement of the feed unit is executed by actuator

B; the vertical movement, by actuators C and D. In the position shown

in the diagram, the parts picked up by the lifting device are inserted

into the box by extending actuator D. At the same time, actuator C

also extends and picks up a square board that is used as an intermedi-

ate layer as two layers of parts are being inserted. As soon as actuator

C has retracted, holding the intermediate layer, the device is moved

by the indexing actuator B. The end position actuator C located above

the box and actuator D located above the collection point are used for

the arrangement of parts.

When actuator C has extended, the intermediate layer is inserted

and the next layer of parts is taken up by actuator D. When actuator

B retracts, the position drawn is reached once again and the second

layer is inserted into the box. Then, when actuator B extends once

again, an intermediate layer is placed on the second layer and the

next parts are picked up.