Page 515 - Sensors and Control Systems in Manufacturing

P. 515

468

Cha p te r

Ni ne

available with the system. However, it is only required when the pro-

gram is transferred into the semiconductor memory. In addition to

this program entry technique, CNC systems offer the possibility of

transferring programs directly from external computers via appro-

priate interfaces.

Moreover, most CNC control systems are equipped with a key-

board and a screen that make it possible to program directly on the

machine. This is referred to as workshop programming. Keyboard

and screen also offer the possibility of editing and improving pro-

grams on site. This is a decisive advantage when compared to NC

systems, where modifications and adaptations are much more

time-consuming.

With microcomputers, it is easy to program the frequently com-

plicated arithmetical operations required for machining complicated

curves. Cutting and feed speed can be matched to the best advantage.

The computer can check and adapt the values continually and thus

determine the most favorable setting values.

Integrated test and diagnostic systems, which are also made pos-

sible by microcomputers, guarantee a high degree of availability for

CNC systems. The control system monitors itself and reports specific

errors independently to the operator.

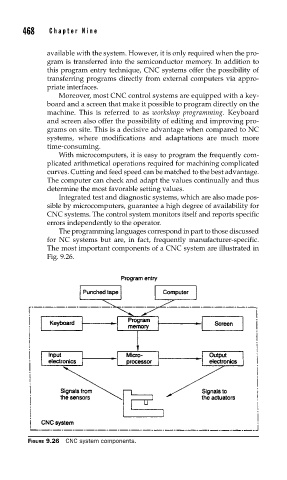

The programming languages correspond in part to those discussed

for NC systems but are, in fact, frequently manufacturer-specific.

The most important components of a CNC system are illustrated in

Fig. 9.26.

FIGURE 9.26 CNC system components.