Page 513 - Sensors and Control Systems in Manufacturing

P. 513

466

Cha p te r

Ni ne

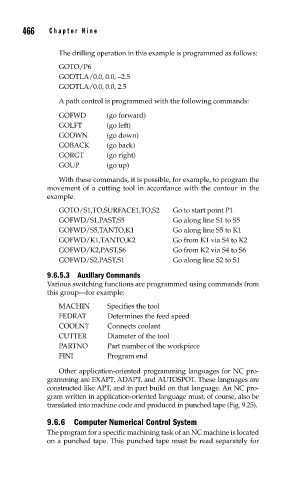

The drilling operation in this example is programmed as follows:

GOTO/P6

GODTLA/0.0, 0.0, –2.5

GODTLA/0.0, 0.0, 2.5

A path control is programmed with the following commands:

GOFWD (go forward)

GOLFT (go left)

GODWN (go down)

GOBACK (go back)

GORGT (go right)

GOUP (go up)

With these commands, it is possible, for example, to program the

movement of a cutting tool in accordance with the contour in the

example.

GOTO/S1,TO,SURFACE1,TO,S2 Go to start point P1

GOFWD/S1,PAST,S5 Go along line S1 to S5

GOFWD/S5,TANTO,K1 Go along line S5 to K1

GOFWD/K1,TANTO,K2 Go from K1 via S4 to K2

GOFWD/K2,PAST,S6 Go from K2 via S4 to S6

GOFWD/S2,PAST,S1 Go along line S2 to S1

9.6.5.3 Auxiliary Commands

Various switching functions are programmed using commands from

this group—for example:

MACHIN Specifies the tool

FEDRAT Determines the feed speed

COOLNT Connects coolant

CUTTER Diameter of the tool

PARTNO Part number of the workpiece

FINI Program end

Other application-oriented programming languages for NC pro-

gramming are EXAPT, ADAPT, and AUTOSPOT. These languages are

constructed like APT, and in part build on that language. An NC pro-

gram written in application-oriented language must, of course, also be

translated into machine code and produced in punched tape (Fig. 9.25).

9.6.6 Computer Numerical Control System

The program for a specific machining task of an NC machine is located

on a punched tape. This punched tape must be read separately for