Page 510 - Sensors and Control Systems in Manufacturing

P. 510

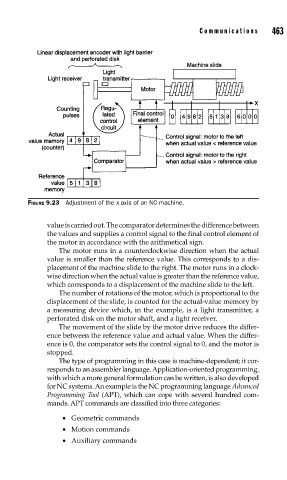

FIGURE 9.23 Adjustment of the x axis of an NC machine. Communications 463

value is carried out. The comparator determines the difference between

the values and supplies a control signal to the final control element of

the motor in accordance with the arithmetical sign.

The motor runs in a counterclockwise direction when the actual

value is smaller than the reference value. This corresponds to a dis-

placement of the machine slide to the right. The motor runs in a clock-

wise direction when the actual value is greater than the reference value,

which corresponds to a displacement of the machine slide to the left.

The number of rotations of the motor, which is proportional to the

displacement of the slide, is counted for the actual-value memory by

a measuring device which, in the example, is a light transmitter, a

perforated disk on the motor shaft, and a light receiver.

The movement of the slide by the motor drive reduces the differ-

ence between the reference value and actual value. When the differ-

ence is 0, the comparator sets the control signal to 0, and the motor is

stopped.

The type of programming in this case is machine-dependent; it cor-

responds to an assembler language. Application-oriented programming,

with which a more general formulation can be written, is also developed

for NC systems. An example is the NC programming language Advanced

Programming Tool (APT), which can cope with several hundred com-

mands. APT commands are classified into three categories:

• Geometric commands

• Motion commands

• Auxiliary commands