Page 506 - Sensors and Control Systems in Manufacturing

P. 506

Communications

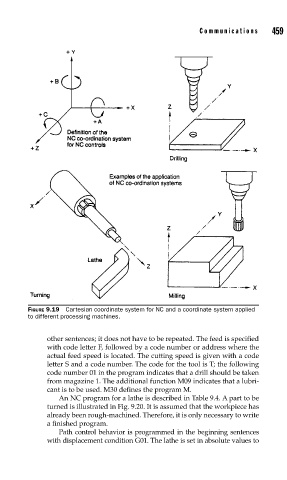

FIGURE 9.19 Cartesian coordinate system for NC and a coordinate system applied 459

to different processing machines.

other sentences; it does not have to be repeated. The feed is specified

with code letter F, followed by a code number or address where the

actual feed speed is located. The cutting speed is given with a code

letter S and a code number. The code for the tool is T; the following

code number 01 in the program indicates that a drill should be taken

from magazine 1. The additional function M09 indicates that a lubri-

cant is to be used. M30 defines the program M.

An NC program for a lathe is described in Table 9.4. A part to be

turned is illustrated in Fig. 9.20. It is assumed that the workpiece has

already been rough-machined. Therefore, it is only necessary to write

a finished program.

Path control behavior is programmed in the beginning sentences

with displacement condition G01. The lathe is set in absolute values to