Page 516 - Sensors and Control Systems in Manufacturing

P. 516

9.7 Industrial Handling Communications 469

The modern term for handling technology is industrial handling or

simply handling. This concept embraces simple and complex handling

and clamping devices.

The best and most versatile handling component is the human

hand. Within its physical limitations of weight and size, many possi-

bilities are available: gripping, allocating, arranging, feeding, posi-

tioning, clamping, working, drawing, transferring, and so on.

Unlike the human hand, a mechanical handling device is able to

perform only a very limited number of functions. For this reason, sev-

eral handling devices have been developed for automatic handling

and clamping functions.

It is not necessary to make a full copy of the human hand. A mechan-

ical device is more or less limited to the shape, size, construction mate-

rial, and characteristics of a specific workpiece to be handled.

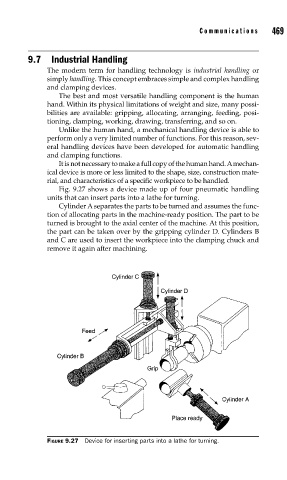

Fig. 9.27 shows a device made up of four pneumatic handling

units that can insert parts into a lathe for turning.

Cylinder A separates the parts to be turned and assumes the func-

tion of allocating parts in the machine-ready position. The part to be

turned is brought to the axial center of the machine. At this position,

the part can be taken over by the gripping cylinder D. Cylinders B

and C are used to insert the workpiece into the clamping chuck and

remove it again after machining.

FIGURE 9.27 Device for inserting parts into a lathe for turning.