Page 572 - Sensors and Control Systems in Manufacturing

P. 572

Economic and Social Inter ests in the Workplace

Product 1 Product 2 525

Sales Product Dollar Products Dollar Total dollar

territory units sales units sales sales

A 1850 14,800 2200 48,400 63,200

B 575 4,600 500 11,000 15,600

C 1400 11,200 1000 22,000 33,200

Total 3825 $30,600 3700 $81,400 $112,000

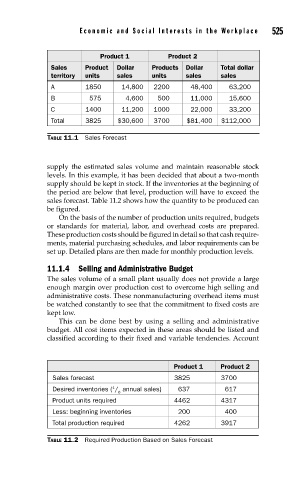

TABLE 11.1 Sales Forecast

supply the estimated sales volume and maintain reasonable stock

levels. In this example, it has been decided that about a two-month

supply should be kept in stock. If the inventories at the beginning of

the period are below that level, production will have to exceed the

sales forecast. Table 11.2 shows how the quantity to be produced can

be figured.

On the basis of the number of production units required, budgets

or standards for material, labor, and overhead costs are prepared.

These production costs should be figured in detail so that cash require-

ments, material purchasing schedules, and labor requirements can be

set up. Detailed plans are then made for monthly production levels.

11.1.4 Selling and Administrative Budget

The sales volume of a small plant usually does not provide a large

enough margin over production cost to overcome high selling and

administrative costs. These nonmanufacturing overhead items must

be watched constantly to see that the commitment to fixed costs are

kept low.

This can be done best by using a selling and administrative

budget. All cost items expected in these areas should be listed and

classified according to their fixed and variable tendencies. Account

Product 1 Product 2

Sales forecast 3825 3700

1

Desired inventories ( / annual sales) 637 617

6

Product units required 4462 4317

Less: beginning inventories 200 400

Total production required 4262 3917

TABLE 11.2 Required Production Based on Sales Forecast