Page 82 - Sensors and Control Systems in Manufacturing

P. 82

44

Cha p te r

T w o

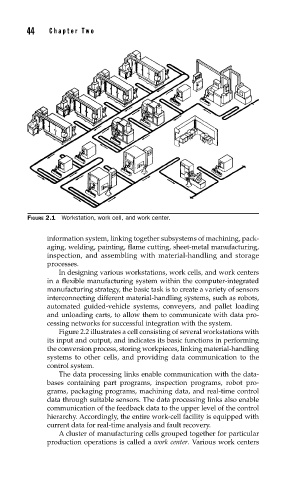

FIGURE 2.1 Workstation, work cell, and work center.

information system, linking together subsystems of machining, pack-

aging, welding, painting, flame cutting, sheet-metal manufacturing,

inspection, and assembling with material-handling and storage

processes.

In designing various workstations, work cells, and work centers

in a flexible manufacturing system within the computer-integrated

manufacturing strategy, the basic task is to create a variety of sensors

interconnecting different material-handling systems, such as robots,

automated guided-vehicle systems, conveyers, and pallet loading

and unloading carts, to allow them to communicate with data pro-

cessing networks for successful integration with the system.

Figure 2.2 illustrates a cell consisting of several workstations with

its input and output, and indicates its basic functions in performing

the conversion process, storing workpieces, linking material-handling

systems to other cells, and providing data communication to the

control system.

The data processing links enable communication with the data-

bases containing part programs, inspection programs, robot pro-

grams, packaging programs, machining data, and real-time control

data through suitable sensors. The data processing links also enable

communication of the feedback data to the upper level of the control

hierarchy. Accordingly, the entire work-cell facility is equipped with

current data for real-time analysis and fault recovery.

A cluster of manufacturing cells grouped together for particular

production operations is called a work center. Various work centers