Page 87 - Sensors and Control Systems in Manufacturing

P. 87

48

T w o

Cha p te r

in-process gauging and production control, and fault recovery derived

from sensors and control systems can enable the manufacturing sys-

tem to increase its own productivity, learn its own limits, and inform

the part programmers of them. The data may also be very useful to the

flexible manufacturing system designers for further analysis. In non-

real-time control systems, the data cannot usually be collected, except

by manual methods, which are time-consuming and unreliable.

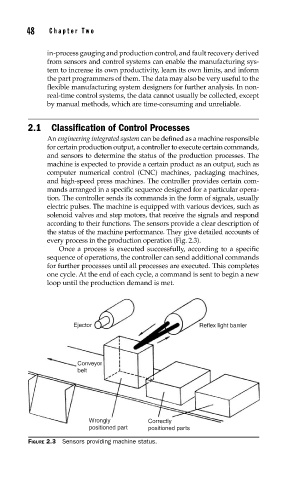

2.1 Classification of Control Processes

An engineering integrated system can be defined as a machine responsible

for certain production output, a controller to execute certain commands,

and sensors to determine the status of the production processes. The

machine is expected to provide a certain product as an output, such as

computer numerical control (CNC) machines, packaging machines,

and high-speed press machines. The controller provides certain com-

mands arranged in a specific sequence designed for a particular opera-

tion. The controller sends its commands in the form of signals, usually

electric pulses. The machine is equipped with various devices, such as

solenoid valves and step motors, that receive the signals and respond

according to their functions. The sensors provide a clear description of

the status of the machine performance. They give detailed accounts of

every process in the production operation (Fig. 2.3).

Once a process is executed successfully, according to a specific

sequence of operations, the controller can send additional commands

for further processes until all processes are executed. This completes

one cycle. At the end of each cycle, a command is sent to begin a new

loop until the production demand is met.

Ejector Reflex light barrier

Conveyor

belt

Wrongly Correctly

positioned part positioned parts

FIGURE 2.3 Sensors providing machine status.