Page 90 - Sensors and Control Systems in Manufacturing

P. 90

Classification and Types of Sensors

to maintain the desired actual value. Where disturbances occur, the 51

course of the actual value must be continuously observed. When

adjustment is made to continuously regulate the actual value, the

loop of action governing measurement, comparison, adjustment, and

reaction within the process is called a closed loop.

2.3 Understanding Photoelectric Sensors

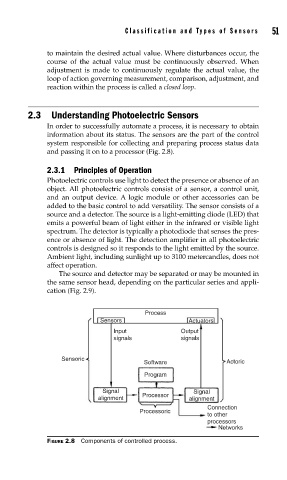

In order to successfully automate a process, it is necessary to obtain

information about its status. The sensors are the part of the control

system responsible for collecting and preparing process status data

and passing it on to a processor (Fig. 2.8).

2.3.1 Principles of Operation

Photoelectric controls use light to detect the presence or absence of an

object. All photoelectric controls consist of a sensor, a control unit,

and an output device. A logic module or other accessories can be

added to the basic control to add versatility. The sensor consists of a

source and a detector. The source is a light-emitting diode (LED) that

emits a powerful beam of light either in the infrared or visible light

spectrum. The detector is typically a photodiode that senses the pres-

ence or absence of light. The detection amplifier in all photoelectric

controls is designed so it responds to the light emitted by the source.

Ambient light, including sunlight up to 3100 metercandles, does not

affect operation.

The source and detector may be separated or may be mounted in

the same sensor head, depending on the particular series and appli-

cation (Fig. 2.9).

Process

Sensors Actuators

Input Output

signals signals

Sensoric

Software Actoric

Program

Signal Signal

alignment Processor alignment

Connection

Processoric

to other

processors

Networks

FIGURE 2.8 Components of controlled process.