Page 128 - Separation process engineering

P. 128

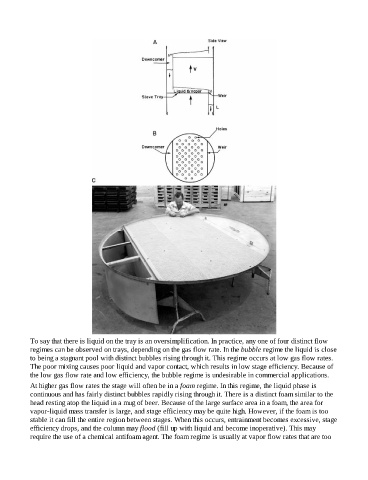

To say that there is liquid on the tray is an oversimplification. In practice, any one of four distinct flow

regimes can be observed on trays, depending on the gas flow rate. In the bubble regime the liquid is close

to being a stagnant pool with distinct bubbles rising through it. This regime occurs at low gas flow rates.

The poor mixing causes poor liquid and vapor contact, which results in low stage efficiency. Because of

the low gas flow rate and low efficiency, the bubble regime is undesirable in commercial applications.

At higher gas flow rates the stage will often be in a foam regime. In this regime, the liquid phase is

continuous and has fairly distinct bubbles rapidly rising through it. There is a distinct foam similar to the

head resting atop the liquid in a mug of beer. Because of the large surface area in a foam, the area for

vapor-liquid mass transfer is large, and stage efficiency may be quite high. However, if the foam is too

stable it can fill the entire region between stages. When this occurs, entrainment becomes excessive, stage

efficiency drops, and the column may flood (fill up with liquid and become inoperative). This may

require the use of a chemical antifoam agent. The foam regime is usually at vapor flow rates that are too