Page 188 - Separation process engineering

P. 188

Since vapor loading requirements are different in different sections of the column (see Chapter 10), the

columns do not have to be the same diameter.

What if the column produces product much purer than specifications? This problem is pleasant. Usually

the reflux ratio can be decreased, which will decrease operating expenses.

Problems with vapor capacity are discussed in more detail in Chapter 10. Briefly, if the column diameter

is not large enough, the engineer can consider:

1. Operating at a reduced L/D, which reduces V. This may make it difficult to meet the product

specifications.

2. Operating at a higher pressure, which increases the vapor density. Note that the column must have

been designed for these higher pressures and the chemicals being separated must be thermally stable.

3. Using two columns in parallel.

4. Replacing the downcomers with larger downcomers (see Chapter 10).

5. Replacing the trays or packing with trays or packing with a higher capacity. Major increases in

capacity are unlikely.

If the column diameter is too large, vapor velocities will be low. The trays will operate at tray

efficiencies lower than designed, and in severe cases they may not operate at all since liquid may dump

through the holes. Possible solutions include:

1. Decrease column pressure to decrease vapor density. This increases the linear vapor velocity.

2. If the column has sieve trays, cover some of the holes. This increases the vapor velocity in the open

holes reducing weeping.

3. Increase L/D to increase V.

4. Recycle some distillate and bottoms product to effectively increase F.

Using existing columns for new uses often requires a creative solution. Such problems can be both

challenging and fun; they are also often assigned to engineers just out of school.

4.14 Subcooled Reflux and Superheated Boilup

What happens if the reflux liquid is subcooled or the boilup vapor is superheated? We have already

looked at two similar cases where we have a subcooled liquid or a superheated vapor feed. In those

cases we found that a subcooled liquid would condense some vapor in the column, while a superheated

vapor would vaporize some liquid. Since reflux and boilup are inputs to the column, we should expect

exactly the same behavior if these streams are subcooled or superheated.

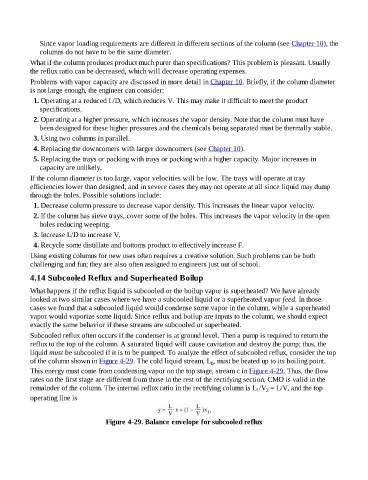

Subcooled reflux often occurs if the condenser is at ground level. Then a pump is required to return the

reflux to the top of the column. A saturated liquid will cause cavitation and destroy the pump; thus, the

liquid must be subcooled if it is to be pumped. To analyze the effect of subcooled reflux, consider the top

of the column shown in Figure 4-29. The cold liquid stream, L , must be heated up to its boiling point.

0

This energy must come from condensing vapor on the top stage, stream c in Figure 4-29. Thus, the flow

rates on the first stage are different from those in the rest of the rectifying section. CMO is valid in the

remainder of the column. The internal reflux ratio in the rectifying column is L /V = L/V, and the top

1

2

operating line is

Figure 4-29. Balance envelope for subcooled reflux