Page 239 - Separation process engineering

P. 239

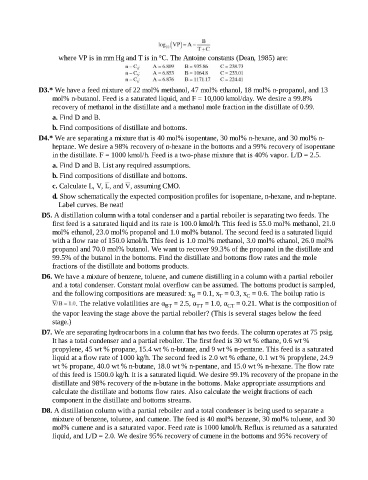

where VP is in mm Hg and T is in °C. The Antoine constants (Dean, 1985) are:

D3.* We have a feed mixture of 22 mol% methanol, 47 mol% ethanol, 18 mol% n-propanol, and 13

mol% n-butanol. Feed is a saturated liquid, and F = 10,000 kmol/day. We desire a 99.8%

recovery of methanol in the distillate and a methanol mole fraction in the distillate of 0.99.

a. Find D and B.

b. Find compositions of distillate and bottoms.

D4.* We are separating a mixture that is 40 mol% isopentane, 30 mol% n-hexane, and 30 mol% n-

heptane. We desire a 98% recovery of n-hexane in the bottoms and a 99% recovery of isopentane

in the distillate. F = 1000 kmol/h. Feed is a two-phase mixture that is 40% vapor. L/D = 2.5.

a. Find D and B. List any required assumptions.

b. Find compositions of distillate and bottoms.

c. Calculate L, V, , and , assuming CMO.

d. Show schematically the expected composition profiles for isopentane, n-hexane, and n-heptane.

Label curves. Be neat!

D5. A distillation column with a total condenser and a partial reboiler is separating two feeds. The

first feed is a saturated liquid and its rate is 100.0 kmol/h. This feed is 55.0 mol% methanol, 21.0

mol% ethanol, 23.0 mol% propanol and 1.0 mol% butanol. The second feed is a saturated liquid

with a flow rate of 150.0 kmol/h. This feed is 1.0 mol% methanol, 3.0 mol% ethanol, 26.0 mol%

propanol and 70.0 mol% butanol. We want to recover 99.3% of the propanol in the distillate and

99.5% of the butanol in the bottoms. Find the distillate and bottoms flow rates and the mole

fractions of the distillate and bottoms products.

D6. We have a mixture of benzene, toluene, and cumene distilling in a column with a partial reboiler

and a total condenser. Constant molal overflow can be assumed. The bottoms product is sampled,

and the following compositions are measured: x = 0.1, x = 0.3, x = 0.6. The boilup ratio is

T

C

B

. The relative volatilities are α = 2.5, α = 1.0, α = 0.21. What is the composition of

TT

BT

CT

the vapor leaving the stage above the partial reboiler? (This is several stages below the feed

stage.)

D7. We are separating hydrocarbons in a column that has two feeds. The column operates at 75 psig.

It has a total condenser and a partial reboiler. The first feed is 30 wt % ethane, 0.6 wt %

propylene, 45 wt % propane, 15.4 wt % n-butane, and 9 wt % n-pentane. This feed is a saturated

liquid at a flow rate of 1000 kg/h. The second feed is 2.0 wt % ethane, 0.1 wt % propylene, 24.9

wt % propane, 40.0 wt % n-butane, 18.0 wt % n-pentane, and 15.0 wt % n-hexane. The flow rate

of this feed is 1500.0 kg/h. It is a saturated liquid. We desire 99.1% recovery of the propane in the

distillate and 98% recovery of the n-butane in the bottoms. Make appropriate assumptions and

calculate the distillate and bottoms flow rates. Also calculate the weight fractions of each

component in the distillate and bottoms streams.

D8. A distillation column with a partial reboiler and a total condenser is being used to separate a

mixture of benzene, toluene, and cumene. The feed is 40 mol% benzene, 30 mol% toluene, and 30

mol% cumene and is a saturated vapor. Feed rate is 1000 kmol/h. Reflux is returned as a saturated

liquid, and L/D = 2.0. We desire 95% recovery of cumene in the bottoms and 95% recovery of